What Is Energy-Efficient Machinery Design? How to Achieve Green Industry

Posted: January 27, 2026 Filed under: Energy Efficient Machinery, Uncategorized | Tags: Energy Efficient Machinery, ESG Machinery, Green Machinery Leave a comment)

Energy efficiency in manufacturing used to be a “nice to have.” Today, it’s quickly becoming a baseline requirement. Between volatile energy prices, tighter regulations, and customer expectations around sustainability, manufacturers are under real pressure to reduce energy use without compromising output.

That’s where energy-efficient machinery design comes in.

In simple terms, energy-efficient machinery is designed to do the same job (or a better one) while using less power. Done right, it lowers operating costs, cuts carbon emissions, and helps companies stay compliant with current standards—while preparing for the next wave of requirements.

Why Energy Efficiency Matters in Manufacturing

In many factories, energy isn’t just another line item, it’s one of the biggest ones. Depending on the industry and process, energy can represent a large share of operating expenses. Improving efficiency can immediately translate into measurable savings, especially in high-duty equipment that runs daily or continuously.

Beyond cost, energy efficiency also supports:

- Lower emissions and stronger ESG performance

- Better long-term competitiveness (especially for suppliers facing sustainability audits)

- Reduced risk as energy regulations become stricter

How Regulations Shape Machinery Choices

Energy-efficient design isn’t happening in a vacuum. Regulations and standards play a major role in what manufacturers buy, build, and upgrade.

A few widely referenced frameworks include:

- ISO 50001: A structured approach to managing energy use across an organization, helping plants track, improve, and maintain performance over time.

- EU Ecodesign Directive: Sets energy performance requirements for many product categories, influencing how machinery is designed and sold in the EU.

- U.S. Energy Policy Act: Includes efficiency standards and encourages investments that reduce energy consumption.

For procurement teams and plant operators, understanding these frameworks helps avoid compliance issues, qualify for incentives where available, and make equipment decisions that won’t become outdated too soon.

Practical Design Strategies That Actually Reduce Energy Use

Energy efficiency isn’t one single feature, it’s usually the result of multiple design decisions working together. Here are some of the most effective approaches used in modern industrial machinery:

1) High-Efficiency Motors and Drives

Motors are often responsible for a significant portion of electricity use in factories. Upgrading to high-efficiency motors is a strong first step, but pairing them with variable frequency drives (VFDs) is where many plants see major gains.

A VFD lets a motor run at the speed required for the load, instead of operating at full power all the time. In many real applications, that can deliver meaningful savings and smoother operation.

2) Lightweight, Durable Materials

Better material choices don’t just improve strength, they can reduce energy loss and extend service life. Lighter moving components can require less power, and durable parts can reduce replacement frequency, downtime, and waste.

3) Heat Recovery and Energy Reuse

In many production environments, heat is treated as a by-product to remove. But excess heat can sometimes be captured and reused. For example, to preheat fluids, support another stage of the process, or reduce the load on heating systems.

Even incremental recovery can reduce total energy demand over time.

4) Automation and Smart Controls

Smart controls help machinery respond to real conditions rather than fixed settings. Sensors and monitoring systems can identify inefficiencies early, prevent energy waste, and keep machines running at optimal settings.

In many plants, improved controls also support better quality consistency and fewer unexpected stoppages—so the benefits extend beyond energy.

Where Energy-Efficient Machinery Is Already Paying Off

Energy-efficient design is no longer theoretical, many industries are already applying it with measurable results:

- Automotive manufacturing often adopts efficient servo motors and energy-saving motion systems on assembly lines.

- Packaging equipment uses VFDs to match speed to load, reducing consumption during low-demand cycles.

- Food processing commonly uses heat exchangers, optimized refrigeration, and smarter temperature control to reduce electricity use.

These examples show a pattern: when efficiency is built into the equipment and control strategy, manufacturers can reduce energy usage while maintaining throughput.

A Practical Starting Point for B2B Decision-Makers

If you’re a procurement officer, engineer, or plant owner, energy efficiency can feel like a huge project. The easiest way to make it manageable is to treat it like any other performance improvement initiative with clear baselines and measurable targets.

A straightforward approach:

- Assess current energy use

Identify which machines consume the most power and run the longest hours. - Prioritize high-impact upgrades

Start with systems where efficiency gains will be largest (motors, compressed air, HVAC, high-duty machinery). - Choose equipment with verified performance data

Ask suppliers for energy consumption metrics, duty cycle assumptions, and ROI estimates—not just general claims. - Monitor after installation

Use metering, IoT dashboards, or analytics tools to confirm savings and adjust parameters over time.

This turns energy efficiency from a vague goal into a trackable business improvement plan.

What’s Next: Trends Shaping Green Machinery Design

Energy-efficient machinery will keep evolving, and a few directions are becoming more common:

- AI-driven predictive maintenance to reduce energy waste caused by wear, misalignment, or failing components

- Circular-economy design (repairability, recyclability, modular parts) to reduce lifecycle impact

- Policy incentives and carbon programs that encourage faster adoption of efficient systems

The manufacturers that stay informed—and invest strategically—are more likely to benefit from both cost savings and market access.

Conclusion

Energy-efficient machinery design is not just about reducing power consumption, it’s a practical way to lower operating costs, cut emissions, and strengthen competitiveness. By understanding relevant standards, applying proven design strategies, and measuring results in real operations, manufacturers can move toward greener industrial performance without sacrificing productivity.

For B2B buyers and decision-makers, prioritizing energy efficiency isn’t simply a sustainability move, it’s a long-term business advantage.

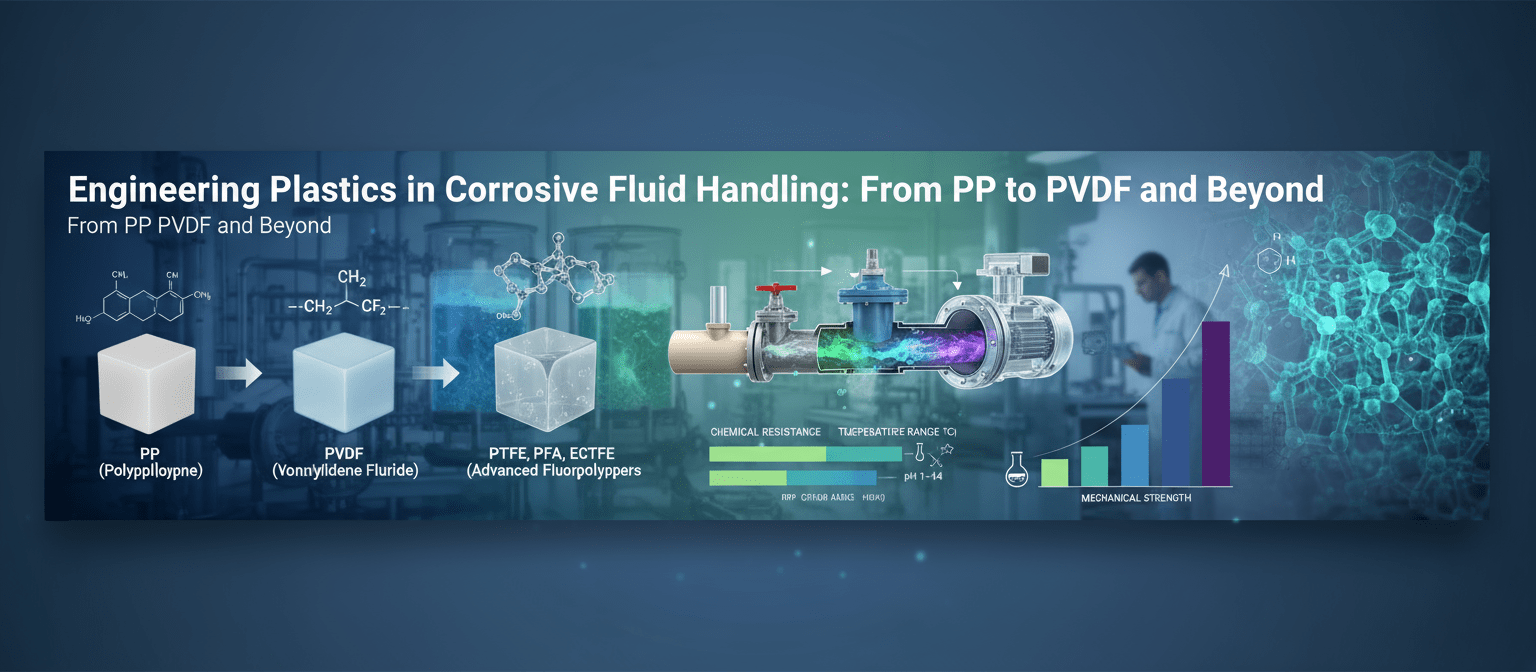

Engineering Plastics in Corrosive Fluid Handling: From PP to PVDF and Beyond

Posted: January 23, 2026 Filed under: Magnetic Drive Pump | Tags: Magnetic Drive Pump, Plastic chemical pump Leave a comment

In corrosive chemical processing, pump failure often traces back to material incompatibility. While traditional metal alloys struggle with acid and solvent exposure, engineering plastics—notably polypropylene (PP), polyvinylidene fluoride (PVDF), and fluoropolymers—have transformed how industries manage aggressive media.

The development of plastic magnetic chemical pumps has been pivotal in this shift. Unlike conventional sealed pumps, magnetic-drive designs prevent leakage and fluid contamination, making them essential for high-purity or hazardous operations.

Polypropylene (PP): Balancing Cost and Resistance

PP remains the most economical option for mild corrosive environments. It demonstrates solid resistance against diluted acids, bases, and salts, maintaining rigidity up to roughly 80°C. However, it loses mechanical strength in high-temperature or oxidizing media, limiting its use in concentrated acid applications.

In general industrial settings—such as neutralization or wastewater treatment—PP’s chemical stability and cost-effectiveness make it a practical choice for non-critical chemical handling.

PVDF: The High-Performance Alternative

For processes involving strong acids, halogens, or oxidizers, PVDF is the preferred polymer. Its semi-crystalline structure and strong carbon–fluorine bonds give it exceptional resistance and dimensional stability even under continuous exposure to chemicals like hydrochloric or sulfuric acid.

Additionally, PVDF withstands UV radiation and maintains low permeability—vital for high-purity applications in semiconductor or pharmaceutical production lines.

Fluoropolymers and Composites: Extending the Performance Envelope

For extreme conditions, PTFE and ETFE offer near-universal chemical inertness. PTFE excels in corrosion resistance but lacks mechanical rigidity, while ETFE bridges this gap by combining strength and processability.

Meanwhile, CFR-PP (Carbon Fiber Reinforced PP) strengthens standard PP’s structure, expanding its usability in mid-temperature, mid-pressure systems.

Such material evolution underscores how corrosion-resistant pump design depends not just on the choice of polymer but on how that material integrates with structural and thermal engineering principles.

Verification and Material Testing

Before implementation, chemical compatibility testing, FEA-based stress analysis, and accelerated aging trials ensure each material’s suitability. Engineers assess both static exposure and dynamic wear, confirming that pump components retain integrity under operational stress.

Conclusion: Material Innovation Driving Reliability

As industries demand safer, cleaner, and more durable systems, plastic materials continue to expand their role in chemical transfer pump manufacturing. Each polymer—PP, PVDF, PTFE—represents a tier of performance tailored to specific chemical and thermal conditions.

ASSOMA INC., a specialist in plastic magnetic chemical pumps, applies decades of material science expertise to help distributors and OEMs identify optimal material solutions. Its engineering team supports global clients through data-driven compatibility consultation and precision pump design.

The Hidden Costs of Choosing the Wrong Tool Holder

Posted: January 7, 2026 Filed under: Manufacturer | Tags: tool holder, tool holders Leave a comment

Every procurement manager understands the pressure of keeping production costs low. However, the wrong tool holder—even if seemingly cost-effective—can create a chain reaction of inefficiency, hidden expenses, and reduced output quality.

In modern CNC machining, the precision of the tool holder determines how effectively power, accuracy, and stability are transmitted from spindle to cutting edge.

Beyond the Purchase Price: The Real Cost Equation

The lowest-priced holder often results in higher long-term costs due to poor precision, increased vibration, and frequent replacements.

In high-speed machining, even a 0.01 mm runout deviation can cause tool breakage, leading to scrap material and rework costs. Over hundreds of machining cycles, these errors accumulate into substantial financial losses.

Procurement professionals should calculate the total cost per machining hour, factoring in tool wear, downtime, and quality yield rate—not just the purchase price of the holder.

How Runout Impacts Profitability

Excessive runout increases tool wear, reduces dimensional consistency, and forces operators to slow feed rates—hurting productivity.

Studies show that runout above 0.005 mm can shorten carbide tool life by 30–40%. It also raises spindle load, which increases maintenance frequency.

When evaluating suppliers, request documented runout test results. Choose holders that guarantee ≤0.003 mm accuracy, especially for finishing or high-speed operations.

Downtime and Maintenance: The Hidden Production Killer

Unreliable tool holders cause frequent stoppages for recalibration or cleaning, disrupting production flow.

In continuous production environments, each unplanned hour of downtime can cost thousands of dollars in idle labor and lost output.

Procurement should favor designs that offer easy balance adjustment, anti-corrosion treatment, and compatible interfaces (BT, HSK, CAT). These features extend uptime and simplify maintenance.

The Supply Chain Factor

Supplier reliability directly affects manufacturing continuity. Delays in tool holder delivery can stall production and customer orders.

Manufacturers with diversified supply networks report up to 25% fewer disruptions caused by late tooling shipments.

Procurement departments should audit supplier logistics, checking average lead time and emergency support capacity. A dependable supplier ensures consistent quality and delivery under tight schedules.

Conclusion: Precision Is Profit

Choosing the right tool holder is not a technical luxury—it’s a financial decision. Precision, durability, and supplier reliability directly determine the cost efficiency of CNC operations.

For distributors and manufacturers seeking a trusted CNC tool holder supplier, Ann Way Machine Tools Co., Ltd. provides ISO-certified, precision-balanced tool holders designed for long-term accuracy and cost savings. With decades of industry experience and global logistics support, Ann Way helps procurement managers reduce hidden costs and achieve reliable machining performance.

Speed is Profit – Switching from Gravity Cups to Pressure Tanks for Large Automotive Jobs

Posted: January 5, 2026 Filed under: Uncategorized Leave a comment

1. The “Hidden” Time Waster in Your Body Shop

Your painter spends 20% of their day mixing paint and refilling cups. That is lost profit.

In the automotive repair business, time is the most valuable asset. The faster a car moves out of the spray booth, the sooner you can bring the next car in. Most body shops use standard “gravity feed” spray guns with a small 600ml plastic cup on top. These are excellent for painting a single door or a fender.

But what happens when you need to paint a whole van, a truck bed, or perform a full-body color change?

The painter sprays for 3 minutes. The cup goes empty. He stops. He opens the cup. He refills it. He closes it. He starts again.

This happens 5, 10, or 20 times per job. This is not just annoying; it is a quality risk. Every time the painter stops, the paint on the car begins to dry. When he starts spraying again, the new wet paint hits the drying paint. This creates a rough texture called “dry spray” or a visible line.

There is a better way. This article explains how switching to RANOX Pressure Paint Tanks can double your speed on large jobs.

2. The Fleet Contract: A Story of Efficiency

Let’s look at a real scenario.

“FastFix Auto Body” received a big contract. A local delivery company needed 50 white vans painted with their new company color.

At first, the shop manager was happy. But after the first week, the painters were exhausted. Painting a large van with a small 600ml cup was a nightmare. They had to refill the cup 15 times for each van. The finish was uneven because the paint mixed in the morning was slightly different from the paint mixed in the afternoon.

The shop manager called a distributor who sold RANOX equipment. The distributor suggested a simple change: A 10-Liter RANOX Pressure Paint Tank.

The process changed immediately.

- The painter mixed 10 liters of white paint at once in the morning.

- He poured it all into the RANOX tank.

- He sprayed 3 vans in a row without stopping once to refill.

The Result: The shop finished the contract two weeks early. The finish was perfectly smooth because the “wet edge” never dried out. The shop made 30% more profit on the job simply by changing the tool.

3. Why Pressure Tanks Are Superior for Auto Refinishing

A pressure paint tank (often called a pressure pot) is a closed container that holds paint. Compressed air pushes the paint out of the tank, through a hose, and into the spray gun.

Benefit 1: Continuous Spraying

With a tank, you can spray upside down. You can spray underneath a truck chassis. You can spray a roof without the cup hitting the surface. The gun is lighter because it does not carry the weight of the paint. The painter gets less tired.

Benefit 2: Handling Thick Materials

Automotive refinishing is not just about color. It involves thick primers, sprayable body fillers (putty), and bed liners (for pickup trucks).

Gravity guns struggle with these thick fluids. They clog easily.

A RANOX pressure tank uses air pressure to force the thick fluid to the gun. You can spray heavy-duty bed liners as easily as water.

Benefit 3: Consistency

When you mix paint in small batches, “Color Shift” is a risk. Even a small error in the mixing ratio can make the bumper look different from the hood. By mixing a large batch in a RANOX tank, every inch of the vehicle gets the exact same shade.

4. The Role of Automatic Spray Guns in Auto Parts

While body shops use manual guns, the Auto Parts Manufacturing sector relies on automation.

If you are a manufacturer making aftermarket bumpers, spoilers, or side mirrors, you cannot paint by hand. It is too slow. You use a robotic arm or a reciprocator.

The RANOX Automatic Advantage

For these manufacturers, RANOX provides automatic spray guns designed for mass production.

- Precision: Our guns maintain a consistent fan width. This is crucial for matching the OEM factory finish.

- Durability: Automotive paints often contain solvents that attack rubber seals. RANOX guns use solvent-resistant seals that withstand daily exposure to harsh chemicals.

For distributors, selling RANOX means you can serve both the local body shop (Tanks) and the local parts factory (Automatic Guns).

5. Technical Feature: The Importance of Agitation

Automotive paint is special. It often contains Metallic Flakes or Pearls.

These are tiny metal particles that make the car sparkle.

The problem? Metal is heavy. If you put metallic paint in a pot and wait 10 minutes, the metal sinks to the bottom.

If you spray this unmixed paint, the first part of the car will have no sparkle (flat color), and the last part will have too much sparkle (dark/grey color).

The RANOX Solution: Air Motor Agitators

RANOX pressure paint tanks come with optional air motor agitators. These motors spin a propeller inside the tank. They keep the paint moving gently.

- It keeps the metal flakes suspended evenly.

- It ensures the color is exactly the same from the first minute to the last minute.

- RANOX air motors are explosion-proof (safe for volatile car paints).

6. When to Use a Tank: The “2-Liter Rule”

How does a shop manager decide when to use a standard gun and when to get the pressure tank?

Here is a simple rule you can teach your staff. It is called the “2-Liter Rule.”

- Job requires less than 2 Liters of paint? (e.g., A bumper, a door, a hood).

- Use: Standard Gravity Gun.

- Why: It is faster to clean up.

- Job requires MORE than 2 Liters of paint? (e.g., A full car, a van, a truck bed, a trailer).

- Use: RANOX Pressure Paint Tank.

- Why: The time you save on not refilling pays for the cleaning time.

7. Safety and Durability: Why RANOX?

Auto body shops are tough environments. Tools get dropped. Solvents get spilled.

Cheap equipment fails quickly here.

One-Piece Shell

Many cheap pressure tanks involve multiple welded parts or thin steel. They can leak or deform under pressure.

RANOX pressure tanks (specifically our smaller 2L, 4L, 10L models) often feature deep-drawn, one-piece shells or high-strength carbon steel/stainless steel construction.

- Safety: No risk of the bottom falling out under pressure.

- Cleaning: Smooth inner surfaces are easier to clean with thinner.

Made in Taiwan Quality

In the automotive world, “Made in Taiwan” is a sign of professional grade tools. RANOX has been manufacturing for decades. We do not just assemble parts; we engineer them. This means when your client needs a spare lid gasket three years from now, we have it.

8. How to Setup Your Auto Paint Station

For the best results, System Integrators and Shop Owners should follow this setup:

- Compressor: Ensure clean, dry air. Water in the line causes bubbles in the clear coat.

- RANOX Pressure Tank: Choose the size based on your average job (10L is the standard for full cars). Equip it with an automatic agitator if you spray metallics.

- Hose Management: Use twin-hoses (one for air, one for fluid). Keep them bundled to avoid scratching the car.

- Spray Gun:

- For Manual use: Connect a high-quality manual pressure-feed gun.

- For Automatic (Parts Factory): Mount the RANOX Automatic Spray Gun on the robot arm.

9. Conclusion: Professional Tools for Professional Finishes

Your customers, the car owners, judge your work by the finish. They look for gloss. They look for color matching. They look for smoothness.

You cannot deliver professional results consistently if your painters are fighting against their equipment. A RANOX pressure paint tank system turns a chaotic, stop-and-start paint job into a smooth, continuous flow.

It saves time. It saves paint. It improves quality.

Upgrade Your Body Shop Today

Are you ready to stop wasting time on refills?

Download our “Automotive Equipment Configuration Guide” to see which paint pressure tank size and automatic paint spray gun model fits your workshop’s daily volume. Contact RANOX for a Distributor Near You.