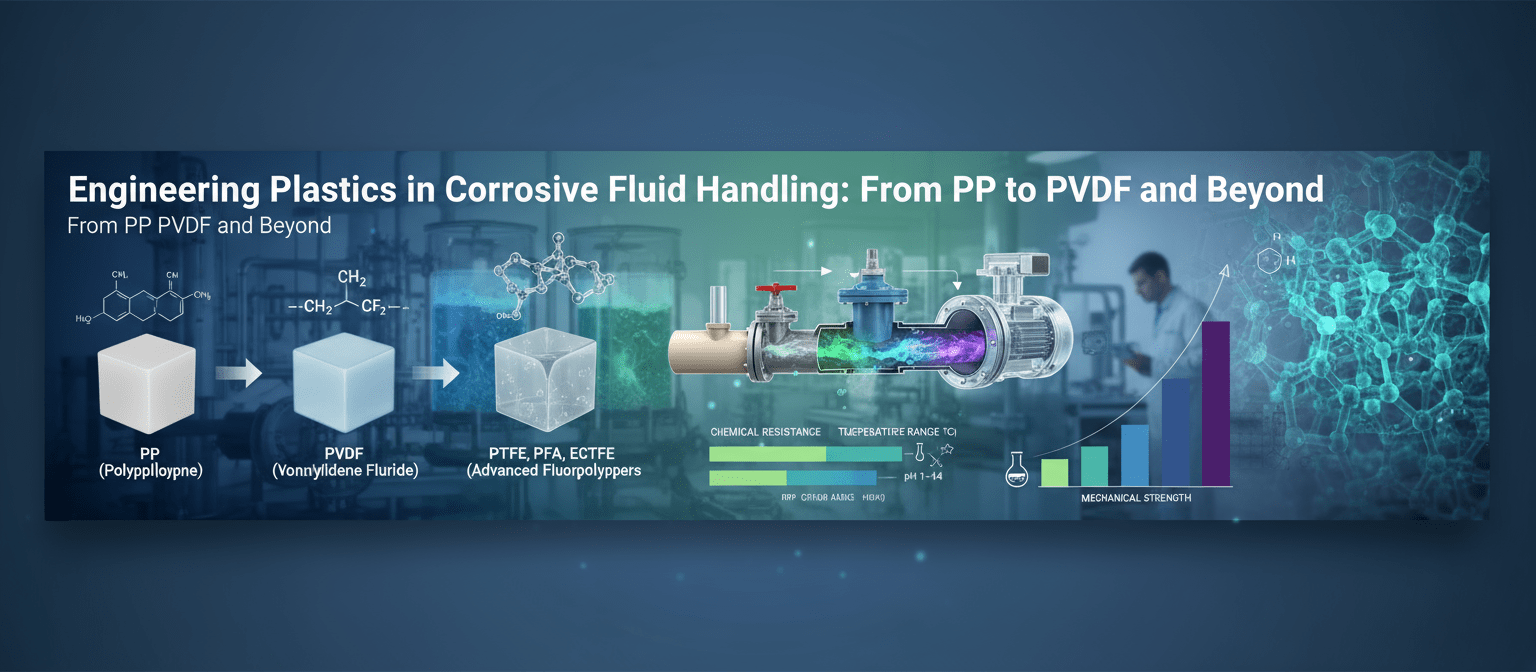

Engineering Plastics in Corrosive Fluid Handling: From PP to PVDF and Beyond

Posted: January 23, 2026 Filed under: Magnetic Drive Pump | Tags: Magnetic Drive Pump, Plastic chemical pump Leave a comment

In corrosive chemical processing, pump failure often traces back to material incompatibility. While traditional metal alloys struggle with acid and solvent exposure, engineering plastics—notably polypropylene (PP), polyvinylidene fluoride (PVDF), and fluoropolymers—have transformed how industries manage aggressive media.

The development of plastic magnetic chemical pumps has been pivotal in this shift. Unlike conventional sealed pumps, magnetic-drive designs prevent leakage and fluid contamination, making them essential for high-purity or hazardous operations.

Polypropylene (PP): Balancing Cost and Resistance

PP remains the most economical option for mild corrosive environments. It demonstrates solid resistance against diluted acids, bases, and salts, maintaining rigidity up to roughly 80°C. However, it loses mechanical strength in high-temperature or oxidizing media, limiting its use in concentrated acid applications.

In general industrial settings—such as neutralization or wastewater treatment—PP’s chemical stability and cost-effectiveness make it a practical choice for non-critical chemical handling.

PVDF: The High-Performance Alternative

For processes involving strong acids, halogens, or oxidizers, PVDF is the preferred polymer. Its semi-crystalline structure and strong carbon–fluorine bonds give it exceptional resistance and dimensional stability even under continuous exposure to chemicals like hydrochloric or sulfuric acid.

Additionally, PVDF withstands UV radiation and maintains low permeability—vital for high-purity applications in semiconductor or pharmaceutical production lines.

Fluoropolymers and Composites: Extending the Performance Envelope

For extreme conditions, PTFE and ETFE offer near-universal chemical inertness. PTFE excels in corrosion resistance but lacks mechanical rigidity, while ETFE bridges this gap by combining strength and processability.

Meanwhile, CFR-PP (Carbon Fiber Reinforced PP) strengthens standard PP’s structure, expanding its usability in mid-temperature, mid-pressure systems.

Such material evolution underscores how corrosion-resistant pump design depends not just on the choice of polymer but on how that material integrates with structural and thermal engineering principles.

Verification and Material Testing

Before implementation, chemical compatibility testing, FEA-based stress analysis, and accelerated aging trials ensure each material’s suitability. Engineers assess both static exposure and dynamic wear, confirming that pump components retain integrity under operational stress.

Conclusion: Material Innovation Driving Reliability

As industries demand safer, cleaner, and more durable systems, plastic materials continue to expand their role in chemical transfer pump manufacturing. Each polymer—PP, PVDF, PTFE—represents a tier of performance tailored to specific chemical and thermal conditions.

ASSOMA INC., a specialist in plastic magnetic chemical pumps, applies decades of material science expertise to help distributors and OEMs identify optimal material solutions. Its engineering team supports global clients through data-driven compatibility consultation and precision pump design.