Stop Losing Money on Idle Machines – The Real Financial Gain of Magnetic Workholding

Posted: February 2, 2026 Filed under: Uncategorized Leave a comment

Your CNC machine costs money every minute. It costs money when it cuts metal. It also costs money when it sits still.

Many factory owners look at the wrong numbers. They look at how fast the machine cuts. But they ignore how long the machine waits. This waiting time is called “setup time.”

If your machine waits for 30 minutes while an operator tightens clamps, you lose production time. If you do this four times a day, you lose two hours of production every day.

This article explains the financial logic behind magnetic workholding. This information helps distributors show factories why magnetic systems are a smart investment, not an extra cost.

The Story of the “Busy” Factory

Let us look at a common situation in a machining factory. We will look at a manager named Mike.

Mike manages a workshop with five CNC machines. He walks through the shop floor. He sees his operators working hard. They are using wrenches. They are tightening screws on mechanical vises. They are cleaning chips out of the slots. They are sweating and working fast.

Mike thinks, “My team is working hard. We are productive.”

But Mike is wrong.

While his operators are turning wrenches, the CNC machines are stopped. A stopped machine produces zero parts. A stopped machine makes zero money. Mike is paying for the electricity, the building, the operator’s salary, and the machine loan. But he gets nothing back during that setup time.

Mike focused on the effort of the workers. He should have focused on the uptime of the spindle.

This is where Earth-Chain Enterprise changes the business.

The Problem: Traditional Clamping is Slow

Traditional mechanical clamps and vises have limits.

- Manual Labor: You must tighten each bolt by hand.

- Obstruction: Clamps cover the top or sides of the part. You cannot machine those areas. You must stop, unclamp, flip the part, reclamp, and find the zero point again.

- Distortion: If you tighten a vise too much, the metal part bends. When you release it, the part springs back and becomes the wrong shape.

This process takes time. It relies on the skill of the operator. If the operator is tired, mistakes happen.

The Solution: Earth-Chain Magnetic Workholding

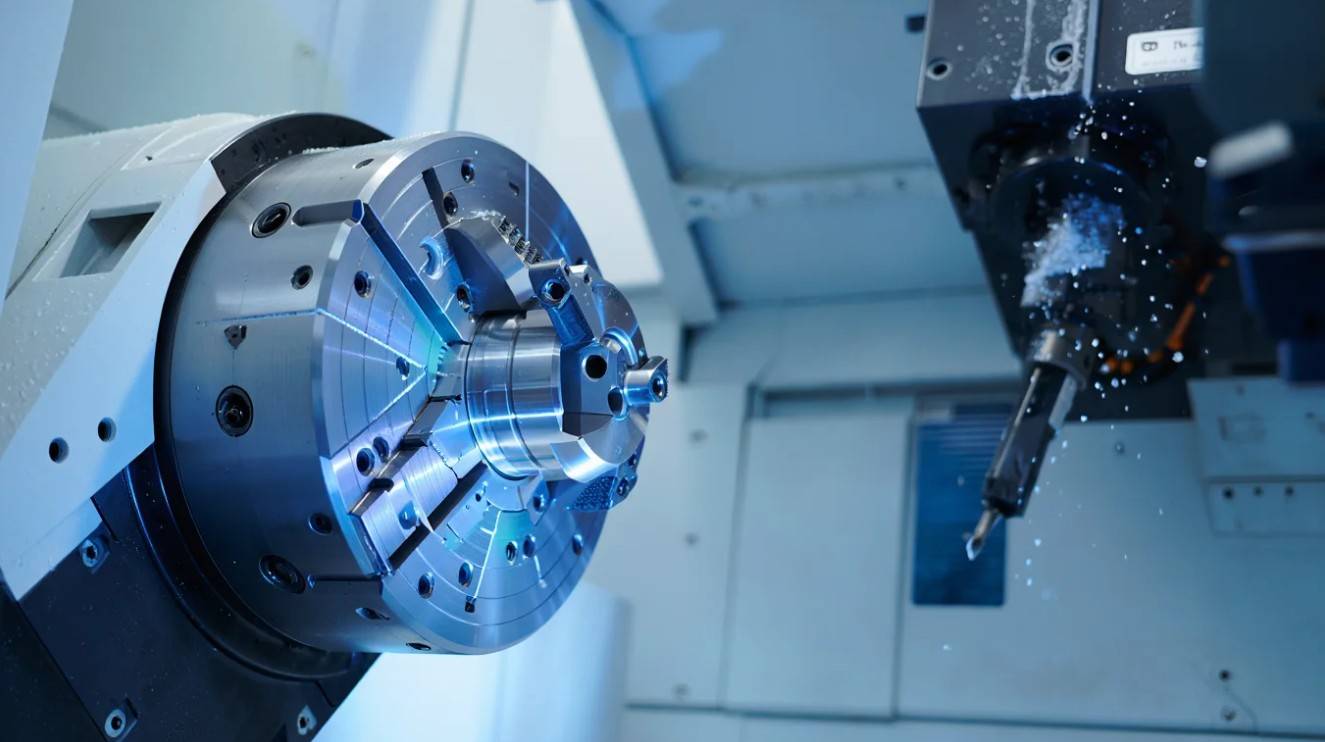

Magnetic workholding systems, manufactured by Earth-Chain Enterprise (ECE), use strong magnets to hold the metal part.

You place the workpiece on the magnetic table. You press a button. In one or two seconds, the machine holds the part with massive force.

The advantages are physical and financial:

- Instant Clamping: Setup takes seconds, not minutes.

- 5-Side Access: The magnet holds the bottom of the part. The top and all four sides are free. You can machine five sides of the part in one setup.

- Uniform Force: The magnet holds the entire surface area. It does not squeeze the part from the side. This prevents vibration and deformation.

ROI Analysis: The Numbers Do Not Lie

Let us calculate the Return on Investment (ROI). This is simple math that any factory owner understands.

Scenario A: Traditional Mechanical Vises

- Machine Hourly Rate: $100

- Setup Time per Part: 15 minutes

- Parts per Day: 4

- Total Setup Cost per Day: 60 minutes = $100 lost per day.

Scenario B: Earth-Chain Magnetic System

- Machine Hourly Rate: $100

- Setup Time per Part: 2 minutes

- Parts per Day: 4

- Total Setup Cost per Day: 8 minutes = $13 lost per day.

The Difference:

By switching to Earth-Chain magnets, you save $87 per day on one machine.

- Monthly Savings (20 days): $1,740

- Yearly Savings: $20,880

This calculation only counts the setup time. It does not count the extra profit from producing more parts in that saved time.

If a magnetic system costs $5,000, the factory earns that money back in less than three months. After three months, the system generates pure profit.

Addressing Safety and Power Failure

Many people ask: “What happens if the power goes out? Will the heavy metal part fall?”

The answer is no.

Earth-Chain Enterprise uses Electro-Permanent Magnetic technology.

- The system needs electricity only for 2 seconds to turn the magnet ON or OFF.

- Once the magnet is ON, it does not need electricity. It is a permanent magnet.

- If the factory loses power, the magnet stays ON. The holding force does not change. The part remains secure forever until you restore power and switch it off intentionally.

This is safer than hydraulic systems, which can lose pressure if a hose breaks.

Why This Matters for the Future

Manufacturing is changing. Skilled workers are hard to find. Factories cannot afford to pay experts to turn wrenches for hours.

Factories must use automation and efficient tools. Earth-Chain’s technology makes the job easier for the operator. It reduces physical stress. It allows a less experienced operator to load parts perfectly every time.

For distributors and agents, this is the key selling point. You are not selling a magnet. You are selling machine capacity. You are selling labor reduction.

3 Immediate Steps to Check Your Efficiency

Do not guess. Check your own factory data today.

- Measure Setup Time: Use a stopwatch. Measure the time from when the machine door opens to remove the old part, until the green button is pressed for the next part.

- Count the Steps: How many times does the operator have to move clamps to reach different sides of the part?

- Check for Scraps: How many parts do you throw away because they were bent by the vise?

If your setup time is more than 20% of your total shift, you need a better solution.

Conclusion

The most expensive thing in a factory is a machine that is not running. Traditional clamps keep machines idle. Earth-Chain magnetic workholding keeps machines running.

Earth-Chain Enterprise provides the technology to turn downtime into profit. The math is simple, and the safety is guaranteed.

Ready to calculate your specific ROI?

Distributors and agents, help your customers see the hidden costs in their factory. Contact Earth-Chain Enterprise today. We will provide you with a detailed ROI calculation sheet and technical support to find the right magnetic solution for your specific CNC machines.

Start saving time. Start making money.