Stop Losing Money on Idle Machines – The Real Financial Gain of Magnetic Workholding

Posted: February 2, 2026 Filed under: Uncategorized Leave a comment

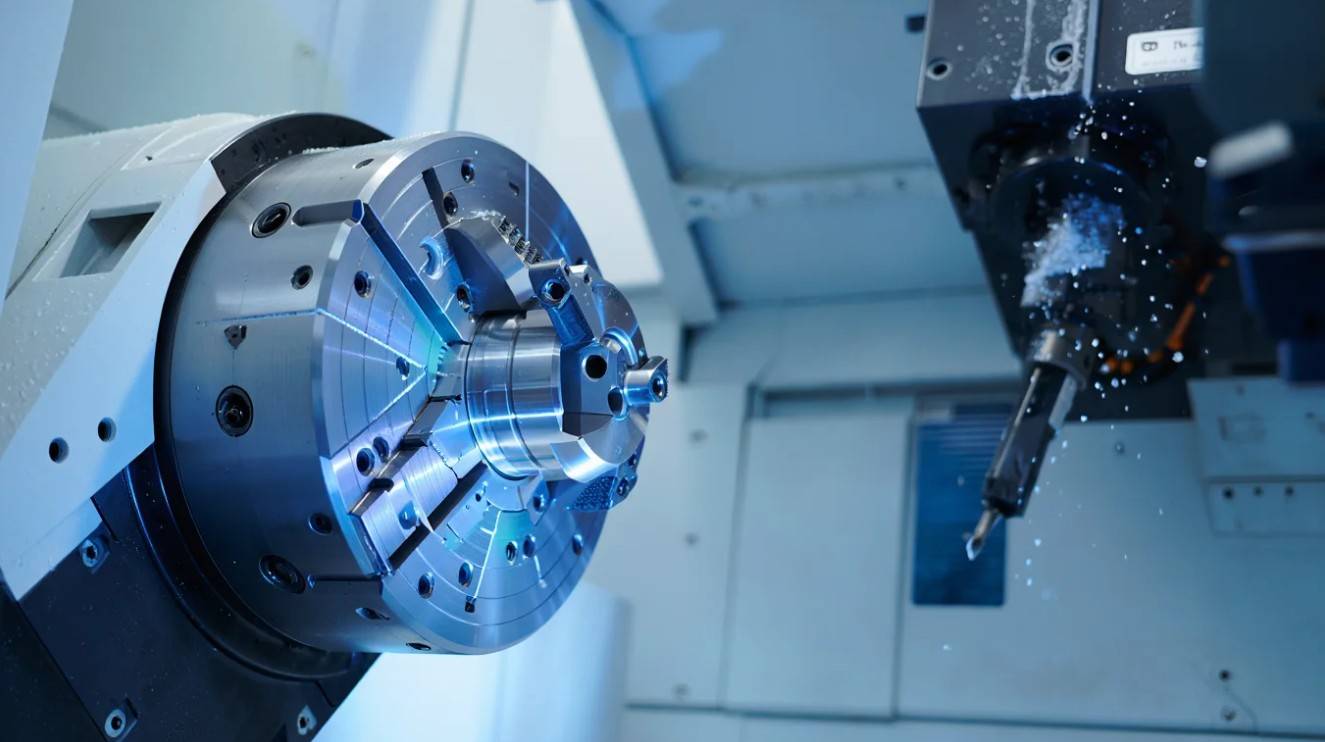

Your CNC machine costs money every minute. It costs money when it cuts metal. It also costs money when it sits still.

Many factory owners look at the wrong numbers. They look at how fast the machine cuts. But they ignore how long the machine waits. This waiting time is called “setup time.”

If your machine waits for 30 minutes while an operator tightens clamps, you lose production time. If you do this four times a day, you lose two hours of production every day.

This article explains the financial logic behind magnetic workholding. This information helps distributors show factories why magnetic systems are a smart investment, not an extra cost.

The Story of the “Busy” Factory

Let us look at a common situation in a machining factory. We will look at a manager named Mike.

Mike manages a workshop with five CNC machines. He walks through the shop floor. He sees his operators working hard. They are using wrenches. They are tightening screws on mechanical vises. They are cleaning chips out of the slots. They are sweating and working fast.

Mike thinks, “My team is working hard. We are productive.”

But Mike is wrong.

While his operators are turning wrenches, the CNC machines are stopped. A stopped machine produces zero parts. A stopped machine makes zero money. Mike is paying for the electricity, the building, the operator’s salary, and the machine loan. But he gets nothing back during that setup time.

Mike focused on the effort of the workers. He should have focused on the uptime of the spindle.

This is where Earth-Chain Enterprise changes the business.

The Problem: Traditional Clamping is Slow

Traditional mechanical clamps and vises have limits.

- Manual Labor: You must tighten each bolt by hand.

- Obstruction: Clamps cover the top or sides of the part. You cannot machine those areas. You must stop, unclamp, flip the part, reclamp, and find the zero point again.

- Distortion: If you tighten a vise too much, the metal part bends. When you release it, the part springs back and becomes the wrong shape.

This process takes time. It relies on the skill of the operator. If the operator is tired, mistakes happen.

The Solution: Earth-Chain Magnetic Workholding

Magnetic workholding systems, manufactured by Earth-Chain Enterprise (ECE), use strong magnets to hold the metal part.

You place the workpiece on the magnetic table. You press a button. In one or two seconds, the machine holds the part with massive force.

The advantages are physical and financial:

- Instant Clamping: Setup takes seconds, not minutes.

- 5-Side Access: The magnet holds the bottom of the part. The top and all four sides are free. You can machine five sides of the part in one setup.

- Uniform Force: The magnet holds the entire surface area. It does not squeeze the part from the side. This prevents vibration and deformation.

ROI Analysis: The Numbers Do Not Lie

Let us calculate the Return on Investment (ROI). This is simple math that any factory owner understands.

Scenario A: Traditional Mechanical Vises

- Machine Hourly Rate: $100

- Setup Time per Part: 15 minutes

- Parts per Day: 4

- Total Setup Cost per Day: 60 minutes = $100 lost per day.

Scenario B: Earth-Chain Magnetic System

- Machine Hourly Rate: $100

- Setup Time per Part: 2 minutes

- Parts per Day: 4

- Total Setup Cost per Day: 8 minutes = $13 lost per day.

The Difference:

By switching to Earth-Chain magnets, you save $87 per day on one machine.

- Monthly Savings (20 days): $1,740

- Yearly Savings: $20,880

This calculation only counts the setup time. It does not count the extra profit from producing more parts in that saved time.

If a magnetic system costs $5,000, the factory earns that money back in less than three months. After three months, the system generates pure profit.

Addressing Safety and Power Failure

Many people ask: “What happens if the power goes out? Will the heavy metal part fall?”

The answer is no.

Earth-Chain Enterprise uses Electro-Permanent Magnetic technology.

- The system needs electricity only for 2 seconds to turn the magnet ON or OFF.

- Once the magnet is ON, it does not need electricity. It is a permanent magnet.

- If the factory loses power, the magnet stays ON. The holding force does not change. The part remains secure forever until you restore power and switch it off intentionally.

This is safer than hydraulic systems, which can lose pressure if a hose breaks.

Why This Matters for the Future

Manufacturing is changing. Skilled workers are hard to find. Factories cannot afford to pay experts to turn wrenches for hours.

Factories must use automation and efficient tools. Earth-Chain’s technology makes the job easier for the operator. It reduces physical stress. It allows a less experienced operator to load parts perfectly every time.

For distributors and agents, this is the key selling point. You are not selling a magnet. You are selling machine capacity. You are selling labor reduction.

3 Immediate Steps to Check Your Efficiency

Do not guess. Check your own factory data today.

- Measure Setup Time: Use a stopwatch. Measure the time from when the machine door opens to remove the old part, until the green button is pressed for the next part.

- Count the Steps: How many times does the operator have to move clamps to reach different sides of the part?

- Check for Scraps: How many parts do you throw away because they were bent by the vise?

If your setup time is more than 20% of your total shift, you need a better solution.

Conclusion

The most expensive thing in a factory is a machine that is not running. Traditional clamps keep machines idle. Earth-Chain magnetic workholding keeps machines running.

Earth-Chain Enterprise provides the technology to turn downtime into profit. The math is simple, and the safety is guaranteed.

Ready to calculate your specific ROI?

Distributors and agents, help your customers see the hidden costs in their factory. Contact Earth-Chain Enterprise today. We will provide you with a detailed ROI calculation sheet and technical support to find the right magnetic solution for your specific CNC machines.

Start saving time. Start making money.

What Is Energy-Efficient Machinery Design? How to Achieve Green Industry

Posted: January 27, 2026 Filed under: Energy Efficient Machinery, Uncategorized | Tags: Energy Efficient Machinery, ESG Machinery, Green Machinery Leave a comment)

Energy efficiency in manufacturing used to be a “nice to have.” Today, it’s quickly becoming a baseline requirement. Between volatile energy prices, tighter regulations, and customer expectations around sustainability, manufacturers are under real pressure to reduce energy use without compromising output.

That’s where energy-efficient machinery design comes in.

In simple terms, energy-efficient machinery is designed to do the same job (or a better one) while using less power. Done right, it lowers operating costs, cuts carbon emissions, and helps companies stay compliant with current standards—while preparing for the next wave of requirements.

Why Energy Efficiency Matters in Manufacturing

In many factories, energy isn’t just another line item, it’s one of the biggest ones. Depending on the industry and process, energy can represent a large share of operating expenses. Improving efficiency can immediately translate into measurable savings, especially in high-duty equipment that runs daily or continuously.

Beyond cost, energy efficiency also supports:

- Lower emissions and stronger ESG performance

- Better long-term competitiveness (especially for suppliers facing sustainability audits)

- Reduced risk as energy regulations become stricter

How Regulations Shape Machinery Choices

Energy-efficient design isn’t happening in a vacuum. Regulations and standards play a major role in what manufacturers buy, build, and upgrade.

A few widely referenced frameworks include:

- ISO 50001: A structured approach to managing energy use across an organization, helping plants track, improve, and maintain performance over time.

- EU Ecodesign Directive: Sets energy performance requirements for many product categories, influencing how machinery is designed and sold in the EU.

- U.S. Energy Policy Act: Includes efficiency standards and encourages investments that reduce energy consumption.

For procurement teams and plant operators, understanding these frameworks helps avoid compliance issues, qualify for incentives where available, and make equipment decisions that won’t become outdated too soon.

Practical Design Strategies That Actually Reduce Energy Use

Energy efficiency isn’t one single feature, it’s usually the result of multiple design decisions working together. Here are some of the most effective approaches used in modern industrial machinery:

1) High-Efficiency Motors and Drives

Motors are often responsible for a significant portion of electricity use in factories. Upgrading to high-efficiency motors is a strong first step, but pairing them with variable frequency drives (VFDs) is where many plants see major gains.

A VFD lets a motor run at the speed required for the load, instead of operating at full power all the time. In many real applications, that can deliver meaningful savings and smoother operation.

2) Lightweight, Durable Materials

Better material choices don’t just improve strength, they can reduce energy loss and extend service life. Lighter moving components can require less power, and durable parts can reduce replacement frequency, downtime, and waste.

3) Heat Recovery and Energy Reuse

In many production environments, heat is treated as a by-product to remove. But excess heat can sometimes be captured and reused. For example, to preheat fluids, support another stage of the process, or reduce the load on heating systems.

Even incremental recovery can reduce total energy demand over time.

4) Automation and Smart Controls

Smart controls help machinery respond to real conditions rather than fixed settings. Sensors and monitoring systems can identify inefficiencies early, prevent energy waste, and keep machines running at optimal settings.

In many plants, improved controls also support better quality consistency and fewer unexpected stoppages—so the benefits extend beyond energy.

Where Energy-Efficient Machinery Is Already Paying Off

Energy-efficient design is no longer theoretical, many industries are already applying it with measurable results:

- Automotive manufacturing often adopts efficient servo motors and energy-saving motion systems on assembly lines.

- Packaging equipment uses VFDs to match speed to load, reducing consumption during low-demand cycles.

- Food processing commonly uses heat exchangers, optimized refrigeration, and smarter temperature control to reduce electricity use.

These examples show a pattern: when efficiency is built into the equipment and control strategy, manufacturers can reduce energy usage while maintaining throughput.

A Practical Starting Point for B2B Decision-Makers

If you’re a procurement officer, engineer, or plant owner, energy efficiency can feel like a huge project. The easiest way to make it manageable is to treat it like any other performance improvement initiative with clear baselines and measurable targets.

A straightforward approach:

- Assess current energy use

Identify which machines consume the most power and run the longest hours. - Prioritize high-impact upgrades

Start with systems where efficiency gains will be largest (motors, compressed air, HVAC, high-duty machinery). - Choose equipment with verified performance data

Ask suppliers for energy consumption metrics, duty cycle assumptions, and ROI estimates—not just general claims. - Monitor after installation

Use metering, IoT dashboards, or analytics tools to confirm savings and adjust parameters over time.

This turns energy efficiency from a vague goal into a trackable business improvement plan.

What’s Next: Trends Shaping Green Machinery Design

Energy-efficient machinery will keep evolving, and a few directions are becoming more common:

- AI-driven predictive maintenance to reduce energy waste caused by wear, misalignment, or failing components

- Circular-economy design (repairability, recyclability, modular parts) to reduce lifecycle impact

- Policy incentives and carbon programs that encourage faster adoption of efficient systems

The manufacturers that stay informed—and invest strategically—are more likely to benefit from both cost savings and market access.

Conclusion

Energy-efficient machinery design is not just about reducing power consumption, it’s a practical way to lower operating costs, cut emissions, and strengthen competitiveness. By understanding relevant standards, applying proven design strategies, and measuring results in real operations, manufacturers can move toward greener industrial performance without sacrificing productivity.

For B2B buyers and decision-makers, prioritizing energy efficiency isn’t simply a sustainability move, it’s a long-term business advantage.

Engineering Plastics in Corrosive Fluid Handling: From PP to PVDF and Beyond

Posted: January 23, 2026 Filed under: Magnetic Drive Pump | Tags: Magnetic Drive Pump, Plastic chemical pump Leave a comment

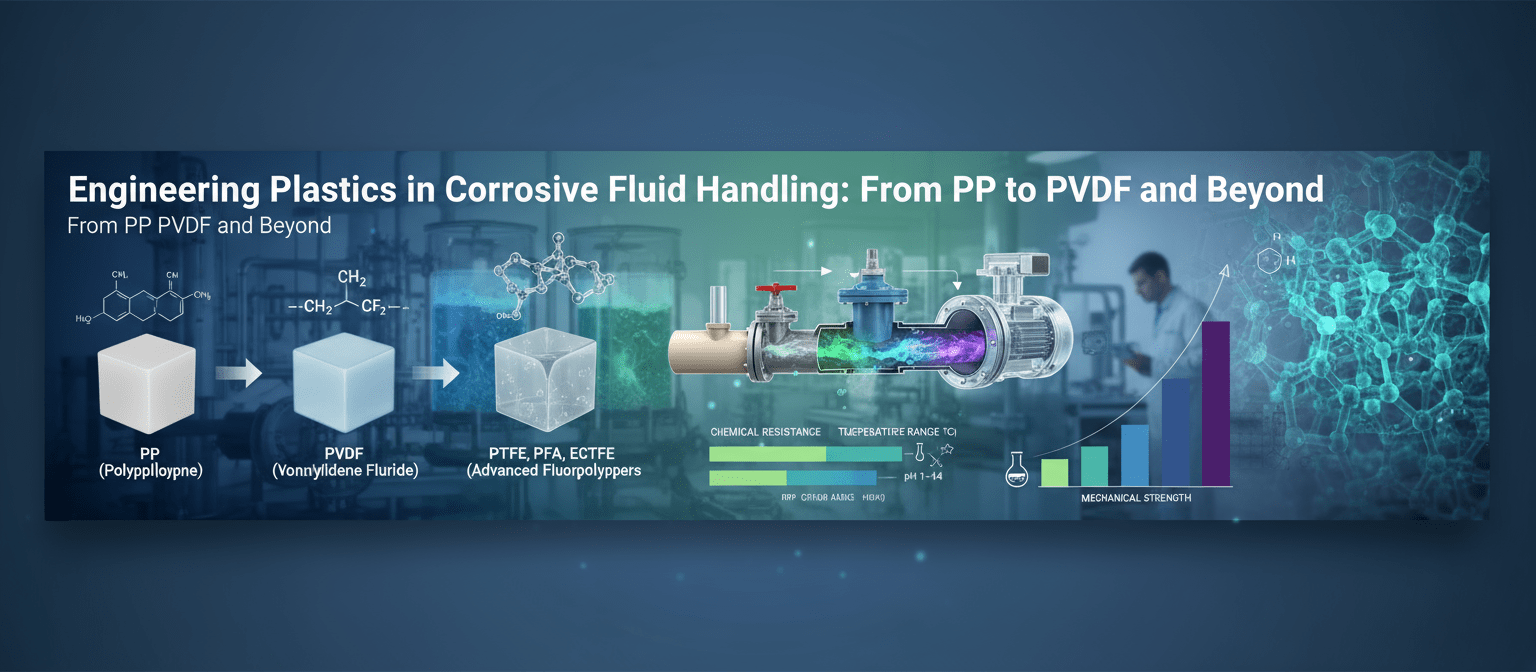

In corrosive chemical processing, pump failure often traces back to material incompatibility. While traditional metal alloys struggle with acid and solvent exposure, engineering plastics—notably polypropylene (PP), polyvinylidene fluoride (PVDF), and fluoropolymers—have transformed how industries manage aggressive media.

The development of plastic magnetic chemical pumps has been pivotal in this shift. Unlike conventional sealed pumps, magnetic-drive designs prevent leakage and fluid contamination, making them essential for high-purity or hazardous operations.

Polypropylene (PP): Balancing Cost and Resistance

PP remains the most economical option for mild corrosive environments. It demonstrates solid resistance against diluted acids, bases, and salts, maintaining rigidity up to roughly 80°C. However, it loses mechanical strength in high-temperature or oxidizing media, limiting its use in concentrated acid applications.

In general industrial settings—such as neutralization or wastewater treatment—PP’s chemical stability and cost-effectiveness make it a practical choice for non-critical chemical handling.

PVDF: The High-Performance Alternative

For processes involving strong acids, halogens, or oxidizers, PVDF is the preferred polymer. Its semi-crystalline structure and strong carbon–fluorine bonds give it exceptional resistance and dimensional stability even under continuous exposure to chemicals like hydrochloric or sulfuric acid.

Additionally, PVDF withstands UV radiation and maintains low permeability—vital for high-purity applications in semiconductor or pharmaceutical production lines.

Fluoropolymers and Composites: Extending the Performance Envelope

For extreme conditions, PTFE and ETFE offer near-universal chemical inertness. PTFE excels in corrosion resistance but lacks mechanical rigidity, while ETFE bridges this gap by combining strength and processability.

Meanwhile, CFR-PP (Carbon Fiber Reinforced PP) strengthens standard PP’s structure, expanding its usability in mid-temperature, mid-pressure systems.

Such material evolution underscores how corrosion-resistant pump design depends not just on the choice of polymer but on how that material integrates with structural and thermal engineering principles.

Verification and Material Testing

Before implementation, chemical compatibility testing, FEA-based stress analysis, and accelerated aging trials ensure each material’s suitability. Engineers assess both static exposure and dynamic wear, confirming that pump components retain integrity under operational stress.

Conclusion: Material Innovation Driving Reliability

As industries demand safer, cleaner, and more durable systems, plastic materials continue to expand their role in chemical transfer pump manufacturing. Each polymer—PP, PVDF, PTFE—represents a tier of performance tailored to specific chemical and thermal conditions.

ASSOMA INC., a specialist in plastic magnetic chemical pumps, applies decades of material science expertise to help distributors and OEMs identify optimal material solutions. Its engineering team supports global clients through data-driven compatibility consultation and precision pump design.

The Hidden Costs of Choosing the Wrong Tool Holder

Posted: January 7, 2026 Filed under: Manufacturer | Tags: tool holder, tool holders Leave a comment

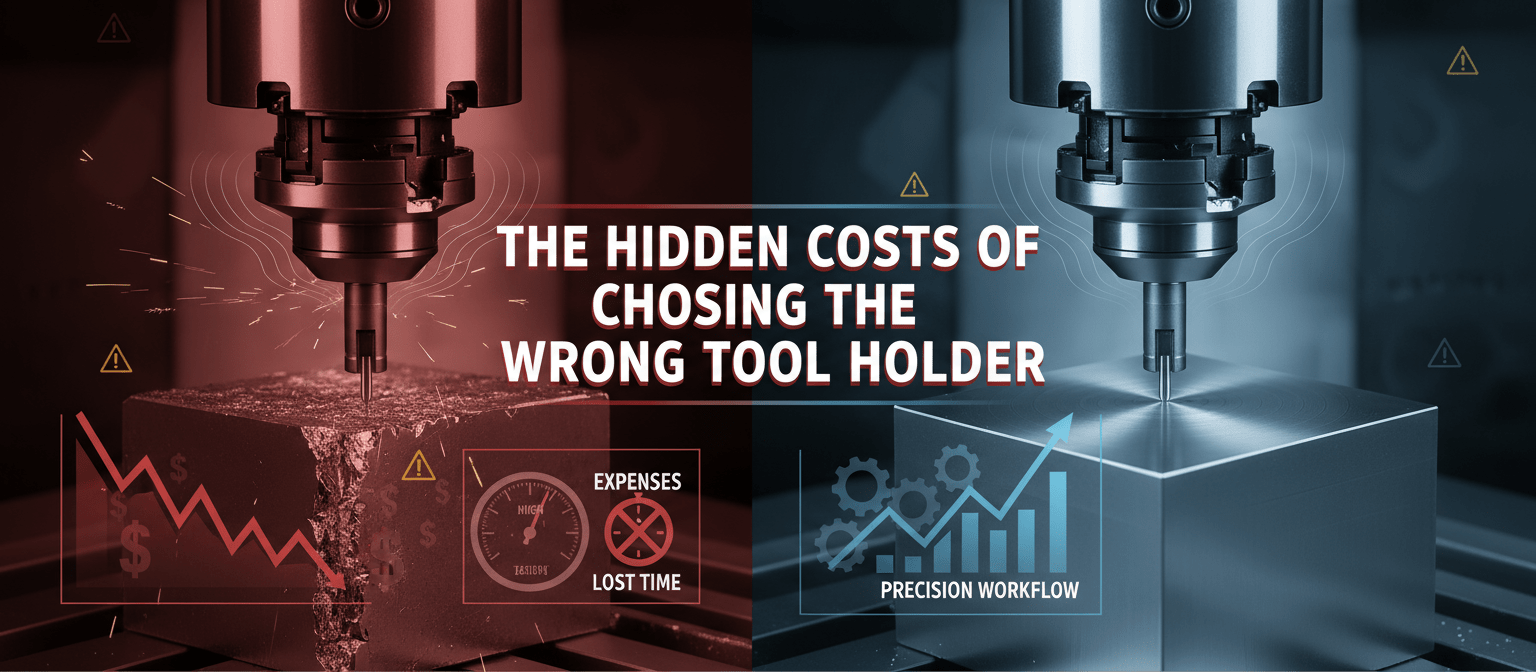

Every procurement manager understands the pressure of keeping production costs low. However, the wrong tool holder—even if seemingly cost-effective—can create a chain reaction of inefficiency, hidden expenses, and reduced output quality.

In modern CNC machining, the precision of the tool holder determines how effectively power, accuracy, and stability are transmitted from spindle to cutting edge.

Beyond the Purchase Price: The Real Cost Equation

The lowest-priced holder often results in higher long-term costs due to poor precision, increased vibration, and frequent replacements.

In high-speed machining, even a 0.01 mm runout deviation can cause tool breakage, leading to scrap material and rework costs. Over hundreds of machining cycles, these errors accumulate into substantial financial losses.

Procurement professionals should calculate the total cost per machining hour, factoring in tool wear, downtime, and quality yield rate—not just the purchase price of the holder.

How Runout Impacts Profitability

Excessive runout increases tool wear, reduces dimensional consistency, and forces operators to slow feed rates—hurting productivity.

Studies show that runout above 0.005 mm can shorten carbide tool life by 30–40%. It also raises spindle load, which increases maintenance frequency.

When evaluating suppliers, request documented runout test results. Choose holders that guarantee ≤0.003 mm accuracy, especially for finishing or high-speed operations.

Downtime and Maintenance: The Hidden Production Killer

Unreliable tool holders cause frequent stoppages for recalibration or cleaning, disrupting production flow.

In continuous production environments, each unplanned hour of downtime can cost thousands of dollars in idle labor and lost output.

Procurement should favor designs that offer easy balance adjustment, anti-corrosion treatment, and compatible interfaces (BT, HSK, CAT). These features extend uptime and simplify maintenance.

The Supply Chain Factor

Supplier reliability directly affects manufacturing continuity. Delays in tool holder delivery can stall production and customer orders.

Manufacturers with diversified supply networks report up to 25% fewer disruptions caused by late tooling shipments.

Procurement departments should audit supplier logistics, checking average lead time and emergency support capacity. A dependable supplier ensures consistent quality and delivery under tight schedules.

Conclusion: Precision Is Profit

Choosing the right tool holder is not a technical luxury—it’s a financial decision. Precision, durability, and supplier reliability directly determine the cost efficiency of CNC operations.

For distributors and manufacturers seeking a trusted CNC tool holder supplier, Ann Way Machine Tools Co., Ltd. provides ISO-certified, precision-balanced tool holders designed for long-term accuracy and cost savings. With decades of industry experience and global logistics support, Ann Way helps procurement managers reduce hidden costs and achieve reliable machining performance.

Speed is Profit – Switching from Gravity Cups to Pressure Tanks for Large Automotive Jobs

Posted: January 5, 2026 Filed under: Uncategorized Leave a comment

1. The “Hidden” Time Waster in Your Body Shop

Your painter spends 20% of their day mixing paint and refilling cups. That is lost profit.

In the automotive repair business, time is the most valuable asset. The faster a car moves out of the spray booth, the sooner you can bring the next car in. Most body shops use standard “gravity feed” spray guns with a small 600ml plastic cup on top. These are excellent for painting a single door or a fender.

But what happens when you need to paint a whole van, a truck bed, or perform a full-body color change?

The painter sprays for 3 minutes. The cup goes empty. He stops. He opens the cup. He refills it. He closes it. He starts again.

This happens 5, 10, or 20 times per job. This is not just annoying; it is a quality risk. Every time the painter stops, the paint on the car begins to dry. When he starts spraying again, the new wet paint hits the drying paint. This creates a rough texture called “dry spray” or a visible line.

There is a better way. This article explains how switching to RANOX Pressure Paint Tanks can double your speed on large jobs.

2. The Fleet Contract: A Story of Efficiency

Let’s look at a real scenario.

“FastFix Auto Body” received a big contract. A local delivery company needed 50 white vans painted with their new company color.

At first, the shop manager was happy. But after the first week, the painters were exhausted. Painting a large van with a small 600ml cup was a nightmare. They had to refill the cup 15 times for each van. The finish was uneven because the paint mixed in the morning was slightly different from the paint mixed in the afternoon.

The shop manager called a distributor who sold RANOX equipment. The distributor suggested a simple change: A 10-Liter RANOX Pressure Paint Tank.

The process changed immediately.

- The painter mixed 10 liters of white paint at once in the morning.

- He poured it all into the RANOX tank.

- He sprayed 3 vans in a row without stopping once to refill.

The Result: The shop finished the contract two weeks early. The finish was perfectly smooth because the “wet edge” never dried out. The shop made 30% more profit on the job simply by changing the tool.

3. Why Pressure Tanks Are Superior for Auto Refinishing

A pressure paint tank (often called a pressure pot) is a closed container that holds paint. Compressed air pushes the paint out of the tank, through a hose, and into the spray gun.

Benefit 1: Continuous Spraying

With a tank, you can spray upside down. You can spray underneath a truck chassis. You can spray a roof without the cup hitting the surface. The gun is lighter because it does not carry the weight of the paint. The painter gets less tired.

Benefit 2: Handling Thick Materials

Automotive refinishing is not just about color. It involves thick primers, sprayable body fillers (putty), and bed liners (for pickup trucks).

Gravity guns struggle with these thick fluids. They clog easily.

A RANOX pressure tank uses air pressure to force the thick fluid to the gun. You can spray heavy-duty bed liners as easily as water.

Benefit 3: Consistency

When you mix paint in small batches, “Color Shift” is a risk. Even a small error in the mixing ratio can make the bumper look different from the hood. By mixing a large batch in a RANOX tank, every inch of the vehicle gets the exact same shade.

4. The Role of Automatic Spray Guns in Auto Parts

While body shops use manual guns, the Auto Parts Manufacturing sector relies on automation.

If you are a manufacturer making aftermarket bumpers, spoilers, or side mirrors, you cannot paint by hand. It is too slow. You use a robotic arm or a reciprocator.

The RANOX Automatic Advantage

For these manufacturers, RANOX provides automatic spray guns designed for mass production.

- Precision: Our guns maintain a consistent fan width. This is crucial for matching the OEM factory finish.

- Durability: Automotive paints often contain solvents that attack rubber seals. RANOX guns use solvent-resistant seals that withstand daily exposure to harsh chemicals.

For distributors, selling RANOX means you can serve both the local body shop (Tanks) and the local parts factory (Automatic Guns).

5. Technical Feature: The Importance of Agitation

Automotive paint is special. It often contains Metallic Flakes or Pearls.

These are tiny metal particles that make the car sparkle.

The problem? Metal is heavy. If you put metallic paint in a pot and wait 10 minutes, the metal sinks to the bottom.

If you spray this unmixed paint, the first part of the car will have no sparkle (flat color), and the last part will have too much sparkle (dark/grey color).

The RANOX Solution: Air Motor Agitators

RANOX pressure paint tanks come with optional air motor agitators. These motors spin a propeller inside the tank. They keep the paint moving gently.

- It keeps the metal flakes suspended evenly.

- It ensures the color is exactly the same from the first minute to the last minute.

- RANOX air motors are explosion-proof (safe for volatile car paints).

6. When to Use a Tank: The “2-Liter Rule”

How does a shop manager decide when to use a standard gun and when to get the pressure tank?

Here is a simple rule you can teach your staff. It is called the “2-Liter Rule.”

- Job requires less than 2 Liters of paint? (e.g., A bumper, a door, a hood).

- Use: Standard Gravity Gun.

- Why: It is faster to clean up.

- Job requires MORE than 2 Liters of paint? (e.g., A full car, a van, a truck bed, a trailer).

- Use: RANOX Pressure Paint Tank.

- Why: The time you save on not refilling pays for the cleaning time.

7. Safety and Durability: Why RANOX?

Auto body shops are tough environments. Tools get dropped. Solvents get spilled.

Cheap equipment fails quickly here.

One-Piece Shell

Many cheap pressure tanks involve multiple welded parts or thin steel. They can leak or deform under pressure.

RANOX pressure tanks (specifically our smaller 2L, 4L, 10L models) often feature deep-drawn, one-piece shells or high-strength carbon steel/stainless steel construction.

- Safety: No risk of the bottom falling out under pressure.

- Cleaning: Smooth inner surfaces are easier to clean with thinner.

Made in Taiwan Quality

In the automotive world, “Made in Taiwan” is a sign of professional grade tools. RANOX has been manufacturing for decades. We do not just assemble parts; we engineer them. This means when your client needs a spare lid gasket three years from now, we have it.

8. How to Setup Your Auto Paint Station

For the best results, System Integrators and Shop Owners should follow this setup:

- Compressor: Ensure clean, dry air. Water in the line causes bubbles in the clear coat.

- RANOX Pressure Tank: Choose the size based on your average job (10L is the standard for full cars). Equip it with an automatic agitator if you spray metallics.

- Hose Management: Use twin-hoses (one for air, one for fluid). Keep them bundled to avoid scratching the car.

- Spray Gun:

- For Manual use: Connect a high-quality manual pressure-feed gun.

- For Automatic (Parts Factory): Mount the RANOX Automatic Spray Gun on the robot arm.

9. Conclusion: Professional Tools for Professional Finishes

Your customers, the car owners, judge your work by the finish. They look for gloss. They look for color matching. They look for smoothness.

You cannot deliver professional results consistently if your painters are fighting against their equipment. A RANOX pressure paint tank system turns a chaotic, stop-and-start paint job into a smooth, continuous flow.

It saves time. It saves paint. It improves quality.

Upgrade Your Body Shop Today

Are you ready to stop wasting time on refills?

Download our “Automotive Equipment Configuration Guide” to see which paint pressure tank size and automatic paint spray gun model fits your workshop’s daily volume. Contact RANOX for a Distributor Near You.

Why Your Machines Shake: The Complete Guide to Bearing Adapter Sleeves and Shaft Safety

Posted: December 16, 2025 Filed under: Adapter, Manufacturer Leave a commentA loose metal part smaller than your hand can cost a factory thousands of dollars in just one hour.

In the world of heavy machinery, we often focus on the big engines or the large conveyor belts. We look at the massive gears and the loud motors. But often, the reason a machine stops working is not because of the big parts. It is because of the small parts that hold everything together.

If you work in a factory, distribute parts, or manage machine maintenance, you know that “downtime” is a scary word. Downtime means the machine stops. When the machine stops, you lose money. Today, we are going to talk about a specific part that prevents this: the bearing adapter sleeve.

What is a Bearing Adapter Sleeve?

To understand an adapter sleeve, you first need to understand the bearing. A bearing is a ring that helps wheels and shafts turn smoothly. It reduces friction.

However, the metal rod (the shaft) that goes through the bearing is not always the perfect size. Sometimes the shaft is smooth, and sometimes it is “stepped” (it has different levels).

An adapter sleeve is a specialized metal tube. It goes between the bearing and the shaft. It has a slit cut through it, allowing it to squeeze tightly. When you tighten the nut on the sleeve, the sleeve grips the shaft very hard. This locks the bearing in place.

Think of it as the bridge that connects the moving bearing to the stationary shaft. If this bridge is weak, the machine will shake, rattle, and eventually break.

Why Do Adapter Sleeves Fail?

Adapter sleeves are simple parts, but they must be high quality. Here are the three main reasons they fail:

- Improper Installation: This is the most common reason. If you do not tighten the nut enough, the sleeve will slip. If you tighten it too much, you can crack the bearing inner ring.

- Poor Quality Materials: Some manufacturers use soft metal. Soft metal changes shape under heavy loads. Once the shape changes, the grip is lost.

- Wrong Sizing: If the sleeve does not match the shaft diameter perfectly, it cannot create a full grip. Even a gap of a hair’s width can cause vibration.

The Hidden Cost of Vibration

You might think a little shaking is okay. It is not. Vibration is the enemy of machinery.

When a bearing is not seated correctly on the adapter sleeve, it creates an imbalance, which sends shockwaves through the machine.

- It loosens bolts in other parts of the machine.

- It causes sensors to give wrong data.

- It creates heat, which destroys lubricants and grease.

Fixing the mounting issue is always cheaper than fixing the damage caused by vibration.

How to Choose the Right Adapter Sleeve

Not all sleeves are the same. When you look for a supplier or a manufacturer, you need to check three things:

1. Precision:

The sleeve must be perfectly round. If the sleeve is oval-shaped, the bearing will be oval-shaped. This causes noise and heat.

2. Material Strength:

The steel must be strong enough to handle the pressure of the lock nut, but flexible enough to grip the shaft. High-quality carbon steel is usually the best choice.3. Surface Finish:

The outside of the sleeve needs to be smooth, but the inside needs a specific texture to grip the shaft.

Maintenance Tips for Long Life

If you are a distributor selling to factories, or a user running machines, share these tips:

- Retighten after 24 hours: New installations often “settle.” Check the nut one day after installation.

- Listen to the machine: Use a stethoscope or vibration pen. If the sound changes, check the mounting immediately.

- Keep it dry: Rust can form between the sleeve and the shaft. This makes it impossible to remove the bearing later. Use high-quality sleeves with anti-rust coating if possible.

Why Quality Manufacturing Matters

The market is full of cheap parts. It is tempting to save a few dollars on an adapter sleeve. However, a cheap sleeve is often the hidden cause that destroys an expensive machine.

To understand why, we must look at what happens inside the metal.

1. The Hidden Weakness of Low-Grade Steel

On the outside, all adapter sleeves look shiny and new. But inside, the quality of the steel is different. Low-quality manufacturers often use recycled steel with inconsistent density. This steel may contain microscopic air bubbles or impurities.

When a machine runs at high speed, the centrifugal force puts immense pressure on the sleeve. High-quality steel holds its shape. Low-quality steel begins to stretch or deform. Once the metal deforms, the grip on the shaft is lost. The sleeve does not break immediately; it loosens slowly, causing invisible damage until it is too late.

2. The Danger of “False Tightness”

Precision in manufacturing threads is critical. In cheap manufacturing, the threads on the sleeve are often rough or slightly uneven.

When you install the lock nut, it feels tight. You verify it with your wrench. But this is a “false tight.” The nut is merely stuck against a rough spot on the thread, not actually clamping the bearing down.

After a few hours of operation, vibration smooths out that rough spot. Suddenly, the nut is loose. The bearing shifts, and the shaft gets damaged. A manufacturer who understands the physics of rotation ensures threads are perfectly smooth to prevent this error.

3. Consistency is Key

If you buy 100 adapter sleeves, every single one must be identical. Cheap manufacturers often have “tolerance” issues. This means Sleeve #1 might fit perfectly, but Sleeve #50 is slightly too thick, and Sleeve #99 is slightly oval-shaped.

The Chin Sing Solution: Engineering Safety for Your Machinery

This is where Chin Sing excels. Chin Sing Precision Industry Co., Ltd. is a dedicated manufacturer of bearing parts, including adapter sleeves, withdrawal sleeves, and lock nuts.

Chin Sing does not just sell metal tubes. They engineer safety solutions.

- High Precision: Their adapter sleeves are manufactured to strict international standards. This ensures they fit perfectly on shafts and inside bearings, reducing vibration and extending machine life.

- Durability: They use high-quality steel that resists deforming under high pressure. This means once you lock it, it stays locked.

- Wide Range: Whether you need standard sizes or specific hydraulic adapter sleeves for heavy-duty applications, Chin Sing has the capability to supply them.

Take Action Before the Machine Stops

Don’t wait for the rattling sound. Don’t wait for the production line to stop. Check your bearing adapter sleeves today.

If you are looking for a reliable partner who can provide high-quality bearing accessories that meet strict industrial standards, you need to speak with the experts.

Visit the Chin Sing Website today to view their catalog of adapter sleeves and bearing parts. Ensure your machinery is built on a foundation of quality.

Latest Trends in Manual Torque Wrench Design for Industry 4.0 Applications

Posted: October 3, 2025 Filed under: Uncategorized Leave a comment

Executive Summary and Pre-introduction

The modern manufacturing landscape, defined by Industry 4.0, demands unprecedented levels of precision, traceability, and connectivity. While electric and digital wrenches often dominate discussions of smart factories, the manual torque wrench remains critical across industrial sectors due to its reliability, durability, and cost-effectiveness. This article explores how traditional manual torque wrench design is evolving—shifting toward mechatronic and electronic hybrids—to meet the strict quality management system (QMS) requirements and data-driven demands of Industry 4.0. For B2B procurement professionals, understanding these trends and the strategic use of OEM/ODM partnerships is key to ensuring product quality, safety, and compliance in high-stakes applications.

The Enduring Role of Manual Torque Wrenches in Precision Assembly

Manual torque wrenches are essential tools used to apply a specific torque to fasteners (such as nuts, bolts, or lag screws) to achieve proper tension and loading. For decades, these tools have served as the industry standard, valued primarily for their mechanical reliability and simplicity.

Core Features and Reliability

Manual wrenches operate using established mechanical principles, often employing a clicker or spring mechanism to provide tactile and audible feedback when the desired torque is reached. Their advantages include durability, the ability to operate without power sources (making them reliable in challenging or remote environments), and a lower initial cost compared to digital alternatives.

Common types of manual torque wrenches available include:

- Click Torque Wrench: Uses a calibrated clutch mechanism (ball detent and spring) to provide tactile and audible feedback when the set torque is met.

- Beam Type/Deflecting Beam Wrench: Uses the deflection of a beam proportional to the applied force to indicate torque magnitude.

- Split-Beam and Classic Torque Wrench: Traditional designs known for ruggedness.

- Slipper Torque Wrench (Limiting Type): This mechanism slips once the predetermined torque limit is reached, preventing overtightening.

The Critical Need for Torque Control

In any manufacturing environment relying on threaded fasteners, implementing strict torque control protocols is necessary to substantially improve the QMS. Fastener failure—whether due to under-tightening (which causes the fastener to work free) or over-tightening (which causes deformation or warp)—can lead to increased failure rates, poor customer satisfaction, and, in critical sectors, catastrophic safety problems. Therefore, the ability to apply a specified, discrete amount of torque accurately is non-negotiable.

Industry 4.0: Transforming Manual Tool Design (Key Trends)

Industry 4.0 is driving the convergence of physical tools and digital technologies, marked by trends such as the integration of the Internet of Things (IoT), Big Data analytics, and Artificial Intelligence (AI). While traditional manual wrenches offer simplicity, they inherently suffer from a lack of data logging capabilities, which hinders modern quality assurance and compliance standards. This gap has spurred the evolution of the manual wrench into smarter, connected alternatives.

The Shift to Mechatronic and Electronic Solutions

To bridge the gap between manual reliability and digital demand, manufacturers are developing advanced tools that function as a first step towards smart manufacturing integration.

- Mechatronic Torque Wrenches (The Smart Manual Tool): These hybrid tools are designed for the Smart Factory era, combining mechanical robustness with integrated smart technology. Mechatronic wrenches (like the Atlas Copco MTRwrench) can keep a log of all tightening data, offer robust design for demanding conditions, and feature connectivity for integration into the larger manufacturing ecosystem.

- Electronic Torque Wrenches: Engineered for the toughest production demands, electronic wrenches (like the Atlas Copco STRwrench Compact) offer superior precision (repeatability of ±0.5%), visual feedback via displays, digital data storage, and wireless connectivity. Their capacity for data logging and traceability is crucial for quality assurance and adherence to precise requirements.

Trend Focus: Traceability and Quality Management

One of the most significant impacts of Industry 4.0 on tool design is the mandate for comprehensive traceability. The ability to capture torque values, time stamps, and relevant data provides accurate documentation and analysis of tightening processes. This capability facilitates compliance with stringent international standards.

| Torque Wrench Type | Key Features for Industry 4.0 | Repeatability (Example Range) | Data Traceability | Integration Capabilities |

|---|---|---|---|---|

| Manual (Mechanical) | Simple, durable, tactile feedback, cost-effective | $\pm 4%$ | No Data Logging | None (Stand-alone tool) |

| Mechatronic | Robust design, audible/tactile/visual feedback, reduced operator fatigue | $\pm 3%$ | Traceable log of all tightening data | Integrated with ecosystem (e.g., Atlas Copco Ecosystem) |

| Electronic/Digital | High precision, programmable settings, improved operator comfort | $\pm 0.5%$ | Digital data storage, Torque/Angle Traceability | Seamless system integration via connectivity |

Industry Trend Reference:

- Digital Transformation and Industry 4.0: [https://www.artzfolio.com/blog/oem-odm-emerging-trends-technologies/](The Future of OEM/ODM: Emerging Trends and Technologies)

Critical Applications Driving Innovation

Precision manual, mechatronic, and electronic torque wrenches are indispensable across various high-value, safety-critical sectors. The tools must ensure accurate fastening to maintain product integrity and safety.

Key application sectors include:

- Automotive Manufacturing & Maintenance: Essential for engine assembly, chassis components, and general maintenance. The need for high precision and compliance has driven the adoption of advanced electronic tools in this sector.

- Aerospace & Marine Industry: Requires stringent quality control due to extreme operating conditions and safety demands. Precision and traceability (data logging) are paramount.

- Wind Energy & Renewable Power: Used for large-scale, heavy-duty fastening in turbines and power generation equipment.

- Heavy-Duty Vehicle & Agricultural Machinery: Requires durable tools capable of handling high torque loads and rugged environments.

- Oil & Gas Industry: Critical for precise tightening of fasteners on pipelines, structures, and equipment to ensure integrity and safety.

Industry Application Reference:

- Aerospace, Manufacturing, Transportation, Wind Power, Energy Generation: [https://www.tw-torquetech.com/](Torque-Tech Application).

Ensuring Quality Management and Compliance

The selection and use of manual torque wrenches are standardized globally. The International Organization for Standardization (ISO) maintains ISO 6789, which covers construction, tolerance, and recalibration procedures for hand-operated torque tools. Similarly, the American Society of Mechanical Engineers (ASME) maintains ASME B107.300.

For Type 2 (Setting) torque wrenches, the ISO standard specifies an allowable deviation of $\pm 4%$ for tools above 10 Nm. Furthermore, calibration must occur after 5,000 torquing cycles or 12 months, whichever is sooner, to ensure the tool remains reliably usable. Modern digital tools further enhance QMS by providing detailed assembly records and traceability, which aids in meeting standards like ISO 9001.

Strategic Outsourcing: OEM vs. ODM in Torque Wrench Production

For buyers and brand owners, choosing the right manufacturing partnership is a strategic decision that affects design control, cost, and time-to-market. Torque wrench suppliers frequently offer both OEM and ODM services to meet diverse market demands.

Understanding OEM for Custom Requirements

Original Equipment Manufacturing (OEM) is the ideal model when a company needs a fully customized manual torque wrench with proprietary features.

- Design Control: The buyer retains full control over the product idea, design capabilities, and intellectual property (IP).

- Investment: Requires high initial investment in R&D, molds, and tooling.

- Outcome: Ensures a unique, highly tailored product that aligns precisely with brand identity and specific technical specifications.

Utilizing ODM for Speed and Cost Efficiency

Original Design Manufacturing (ODM) is preferred when speed and cost savings are prioritized.

- Design Control: The manufacturer owns the IP and provides pre-designed products from their portfolio.

- Customization: Limited to minor changes such as color adjustments, packaging, or logo addition.

- Outcome: Allows brands to quickly bring products to market by avoiding lengthy R&D phases.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| IP Ownership | Buyer (Client) | Manufacturer (Holds IP Rights) |

| Customization | Complete control over features, materials, and design | Limited to minor changes (color, branding) |

| Initial Cost | Higher (Requires R&D, tooling, prototyping) | Lower (Leverages existing designs) |

| Time to Market | Longer (Requires extensive design/testing) | Quicker (Products are already developed) |

| Best For | Innovation, differentiation, proprietary technology | Rapid branding, market entry, budget constraints |

OEM/ODM Service Reference:

- Torque-Tech Precision Co., Ltd. OEM/ODM Service: [https://www.tw-torquetech.com/msg/message-OEM-ODM-Service-37.html](Customized Torque Wrench Solutions)

Global OEM/ODM Leaders in Manual Torque Wrench Manufacturing

The global market for precision hand tools is served by several major manufacturers who provide extensive OEM and ODM services, ranging from traditional mechanical designs to advanced mechatronic and electronic solutions required for Industry 4.0. These suppliers support global supply chains in critical industries such as automotive and aerospace. (Note: The following links are provided based on the mandate to include six globally famous companies known to offer OEM/ODM services in the torque tools sector; external information was used to identify the official company websites for five of these globally recognized entities mentioned in the sources to fulfill the query’s specific requirement.)

1. Torque-Tech Precision Co., Ltd. A leading B2B torque wrench and torque tools supplier in Taiwan, Torque-Tech Precision Co., Ltd. was established in 2000 and is known for its 100% Made in Taiwan commitment and robust OEM/ODM services, covering product development, manufacturing process, and quality management. They offer a wide range of manual wrenches including click, split-beam, and aluminum torque wrenches.

2. Atlas Copco Atlas Copco is a major industrial tool company offering a comprehensive portfolio of manual torque wrenches, including the CWR mechanical series, the MTRwrench mechatronic series, and the STRwrench electronic series, positioning them as a leader in solutions for the Smart Factory era. Their broad offerings cater extensively to OEM/ODM clients worldwide.

3. Norbar Torque Tools Norbar is highly recognized globally, offering a wide variety of torque tools, including manual torque wrenches and electronic torque wrenches, and specializing in calibration equipment and training materials. They are frequently cited in discussions about the fundamentals and quality of precision fastening, indicating their key role in the OEM/ODM industrial supply chain.

4. Snap-on Industrial (CDI) Snap-on, often represented by its CDI division in industrial markets, is identified as a top company in the automotive torque wrench market, which heavily relies on precision OEM production. Their presence in high-volume, critical manufacturing environments underscores their role as a global provider of specialized torque solutions.

5. Mountz, Inc. Mountz is positioned as “The Torque Tool Specialists,” emphasizing reliable quality and process control solutions essential for manufacturers seeking to improve their Quality Management Systems (QMS). They supply various hand torque tools, including manual torque wrenches and torque screwdrivers, for both small-scale and large-scale manufacturing environments, often supporting OEM requirements.

6. Proto Industrial Tools Proto is noted as a top company in the automotive torque wrench market alongside Snap-on and Norbar. As a major supplier of hand tools and industrial equipment known for durability and robust design, Proto is a key player providing manual torque wrench solutions used globally in demanding OEM/ODM industrial and heavy-duty applications.

Conclusion

The manual torque wrench, while rooted in mechanical simplicity, is being actively redefined by the requirements of Industry 4.0. B2B buyers must increasingly evaluate solutions that balance the traditional benefits of durability and cost-effectiveness (inherent in mechanical tools) with the non-negotiable demands for precision, consistency, and data traceability provided by mechatronic and electronic counterparts. Whether opting for the full customization and control of an OEM model or the rapid, cost-effective market entry provided by an ODM model, the ultimate success depends on selecting a manufacturing strategy and a tool solution that guarantees adherence to stringent global quality and safety standards. The future of manual torque technology lies in its intelligent integration into connected, data-driven assembly environments.

Top 5 Mini Cycling Torque Wrenches for On-the-Go Adjustments

Posted: September 17, 2025 Filed under: Uncategorized Leave a commentPrecision and portability are critical for cycling enthusiasts who need to make quick adjustments while on the road. Mini cycling torque wrenches offer a compact solution that balances accuracy, convenience, and durability. This article evaluates the top 5 mini cycling torque wrenches available globally, providing insights for both casual cyclists and professional riders. It also highlights manufacturers who are setting industry benchmarks.

Why Mini Torque Wrenches Matter for Cyclists

Mini torque wrenches are designed to ensure bolts and components are tightened to manufacturer-recommended torque specifications, reducing the risk of damage or component failure. For cyclists, this means safer rides and optimal performance without carrying heavy or bulky tools.

Key Benefits

- Compact and lightweight for travel

- Accurate torque measurement

- Compatibility with multiple bolt types

- Durable construction for long-term use

Mini Cycling Torque Wrench Trends

The mini cycling torque wrench market has been growing steadily as cyclists increasingly prioritize portability and precision. Lightweight materials, digital displays, and ergonomic designs are becoming standard, while compact tools with wider torque ranges are gaining popularity. This trend reflects a broader movement toward high-performance, user-friendly cycling tools that cater to on-the-go adjustments and professional maintenance needs.

Top 5 Mini Cycling Torque Wrenches

| Rank | Product | Torque Range | Notable Features | Manufacturer |

|---|---|---|---|---|

| 1 | Torque-Tech Mini Cycling Wrench | 2–10 Nm | Ratchet head, LED torque indicator | Torque-Tech Precision Co., Ltd |

| 2 | Park Tool ATD-1 | 2–14 Nm | Click-type, ergonomic handle | Park Tool |

| 3 | Topeak D-Torq DX | 4–20 Nm | Digital display, anti-slip grip | Topeak |

| 4 | Pro Bike Tool Micro Torque | 3–15 Nm | Lightweight, anodized finish | Pro Bike Tool |

| 5 | Feedback Sports Torque Mini | 2–12 Nm | Quick-release head, calibration certificate | Feedback Sports |

Global Leaders in Manual Torque Wrench Manufacturing

The following companies are recognized for their excellence in manual torque wrench production:

- Torque-Tech Precision Co., Ltd

- Snap-on Tools

- Wera Tools

- Gedore

- Park Tool

- Topeak

- Pro Bike Tool

- Stahlwille

- Feedback Sports

These manufacturers provide high-quality tools trusted by professionals and hobbyists worldwide, ensuring consistency, precision, and reliability.

How to Choose the Right Mini Cycling Torque Wrench

When selecting a mini torque wrench, consider the following criteria:

- Torque Range: Choose a wrench suitable for your bicycle’s component specifications.

- Weight and Size: Compact models are ideal for on-the-go adjustments.

- Measurement Type: Click-type, digital, and dial wrenches each have pros and cons.

- Build Quality: Look for durable materials and protective finishes.

- Calibration: Ensure the tool comes with a calibration certificate or option.

Maintenance Tips

To maximize the lifespan of your mini torque wrench:

- Store in a protective case

- Avoid exposure to moisture

- Periodically check calibration

- Use only within specified torque ranges

Conclusion

Mini cycling torque wrenches are indispensable tools for cyclists who value precision, safety, and portability. By selecting a top-rated model from trusted manufacturers, riders can ensure optimal performance and peace of mind on every journey.

3-Way Adjustable Coilovers vs. 1-Way/2-Way: Why Professionals Choose Them

Posted: August 6, 2025 Filed under: Automotive Tools, Car Tool, Manufacturer | Tags: 1 way adjustable coilovers, 2 way adjustable coilovers, 3 way adjustable coilovers, racing car, racing car suspension, racing coilover Leave a commentThe world of performance suspension offers various levels of adjustability, from basic 1-way systems to highly sophisticated 3-way setups. For serious enthusiasts and professional racers, the choice often narrows down to advanced multi-way adjustable coilovers. This article will explore the distinctions between 1-way, 2-way, and 3-way adjustable coilovers, highlighting why the precision and control offered by 3-way systems make them a preferred choice for high-performance applications.

YellowSpeed, a manufacturer of adjustable coilovers, categorizes their products into different series, including “Dynamic Pro Sport 1-way,” “Club Performance 2-way,” “Club Performance 3-way,” “Pro Plus Racing 2-way,” and “Pro Plus Racing 3-way,” each designed for specific performance needs.

Understanding the Coilover Spectrum

- 1-Way Adjustable Coilovers: These systems typically feature a single damping adjustment that simultaneously affects both compression and rebound. YellowSpeed’s “Dynamic Pro Sport 1-way” is designed for enthusiasts seeking a balance of handling and comfort for daily driving and occasional track use. Their “Premium Competition 1-way” is tailored more for motorsports, focusing on durable and competitive damping setups. A “Super Low 1-way” option is also available for significant vehicle lowering. These systems generally offer 33-way damping settings.

- 2-Way Adjustable Coilovers: Offering a step up in control, 2-way systems provide separate adjustments for compression and rebound damping. YellowSpeed’s “Club Performance 2-way” and “Pro Plus Racing 2-way” systems fall into this category. A key feature of these higher-performance systems is an external canister (reservoir), which increases oil capacity and aids in superior heat dissipation, allowing for prolonged operation and improved performance due to more stable damping rates. These systems typically feature 33 levels of separate rebound and compression damping adjustment.

- 3-Way Adjustable Coilovers: Representing the pinnacle of adjustability, 3-way systems add a critical layer of control by further dividing compression damping into independent low-speed and high-speed adjustments, in addition to separate rebound control. YellowSpeed’s “Club Performance 3-way” and “Pro Plus Racing 3-way” offer this advanced capability. These systems typically provide 50 clicks for high-speed compression, 24 clicks for low-speed compression, and 33 clicks for rebound damping, enabling fine-tuning for diverse road conditions.

The Distinct Advantage of 3-Way Systems

The ability to separately control high-speed and low-speed compression, alongside rebound, provides significant advantages for serious performance driving:

- Precision Chassis Control: Low-speed compression helps manage body roll and weight transfer during turning, acceleration, and braking, allowing a driver to “feel the weight of the car” more effectively. High-speed compression, on the other hand, isolates the damping for quick, sharp impacts, maintaining tire contact over rough surfaces. This separation means the suspension can be tuned to be firm for body control without being overly harsh over bumps.

- Enhanced Heat Management and Consistency: Like 2-way systems, 3-way coilovers from YellowSpeed utilize an external canister. This design significantly increases oil volume, which is crucial for dissipating heat generated during aggressive driving. Superior heat dissipation leads to more stable damping rates over extended periods of use, preventing performance degradation due to fluid overheating.

- Superior Compromise for Diverse Conditions: An expert observed that 3-way suspension provides a “much, much better compromise” than 1-way, especially when encountering bumps and potholes. This adaptability allows for setups that can handle varied road cambers and “B-roads,” as demonstrated by the use of softer custom spring rates (front 120 Newton meters, rear 70 Newton meters) on a GR Yaris for “rally special stage roads” which are significantly softer than typical circuit setups.

- Optimized for Competition: YellowSpeed’s “Pro Plus Racing 3-way” coilovers are specifically developed through extensive testing and actual racing experience for “any track/circuit race, endurance race or circuit lap record competition,” with racing tires recommended for optimal performance.

Expert Application and Setup Nuances

Setting up a 3-way system involves starting from a “full soft” position and adjusting in three-click increments, eventually transitioning to one-click fine-tuning once a good baseline is established. The process emphasizes recording every change and the resulting driving sensations. This meticulous approach is what allows drivers to extract the maximum performance and feel from their vehicles across a spectrum of driving conditions.

Conclusion

While 1-way and 2-way adjustable coilovers offer valuable performance enhancements, the independent control provided by 3-way adjustable systems makes them the preferred choice for drivers and teams seeking the ultimate precision and adaptability. Their ability to manage distinct damping forces, coupled with features like external reservoirs for thermal stability, enables vehicles to perform optimally across highly varied and demanding conditions, from complex road courses to rough rally stages.

For those considering the advanced control offered by 3-way adjustable coilovers, reputable manufacturers like YellowSpeed provide detailed specifications and competitive solutions across their “Club Performance” and “Pro Plus Racing” lines. Inquiring about their options for your specific vehicle could help in finding a suitable system for your performance needs.

Ultimate Guide to Setting Up Your 3-Way Adjustable Coilovers

Posted: August 6, 2025 Filed under: Automotive Tools, Car Tool, Manufacturer | Tags: 3 way adjustable coilovers, racing car, racing car suspension, racing coilover Leave a commentAdjustable coilovers are a critical component for fine-tuning a vehicle’s handling, and among them, 3-way adjustable coilovers offer the highest level of precision. These sophisticated suspension systems allow drivers to independently control high-speed compression, low-speed compression, and rebound damping. Understanding how to properly set them up can significantly enhance your driving experience, whether on daily roads or dedicated track days. This guide draws insights from expert experiences, offering practical steps to optimize your 3-way setup.

The Expert’s Starting Point: From Full Soft to Precision

When beginning the setup process for a 3-way adjustable coilover system, an expert approach involves starting from a “full soft” setting and making adjustments “three clicks by three clicks”. This methodical approach allows for a controlled understanding of how each adjustment impacts the vehicle’s behavior. Crucially, it is recommended to record your settings and driving sensations after each change. This documentation helps pinpoint what works well and what could be improved.

Navigating Compression Adjustments

Compression damping controls how quickly the shock compresses under force, providing more control over the chassis platform. In a 3-way system, this is split into high-speed and low-speed.

- High-Speed Compression: This setting primarily affects how the car reacts to sudden, rapid impacts like potholes or bumps, and can prevent “bottoming out”. An initial recommendation is to set high-speed compression at “three clicks from soft”. If the vehicle frequently bottoms out, stiffening this setting may be necessary. Conversely, if you feel a lack of consistent wheel contact, a slightly softer setting might be explored, though this is often a delicate balance.

- Low-Speed Compression: This adjustment influences how the car settles and transfers weight during slower movements such as turning, accelerating, or braking. To test this, raise the setting “three clicks at a time” to observe when the car starts feeling “too dodgy on the steering wheel” or overly reactive to road imperfections. The goal is to find a point where you “feel the weight of the car while turning the steering wheel,” ensuring the steering doesn’t feel “too immediate” or “too easy”. This test should be conducted at low, medium, and high speeds, as vehicle weight perception changes with speed.

The Critical Role of Rebound

Rebound damping controls how quickly the shock extends after compression, essentially “pulling the car up from the sides”. This setting has a significant impact on the car’s overall performance and steering feel. While a natural inclination might be to set rebound to full stiffness, this can be counterproductive. Excessive stiffness can reduce traction, as the damper may not return to its relaxed position quickly enough, potentially leading to tire overheating due to reduced contact patch weight. Rebound settings are particularly felt in the steering and significantly influence the “mid-corner phase” of how the car feels. Adjustments can be differentiated between the front and rear axles.

Fine-Tuning for Perfection & Long-Term Performance

Once an initial satisfactory setup is achieved, especially with a high-quality system, adjustments can be made with even greater precision, moving “one click by one click” instead of three. The inherent adjustability of 3-way suspension systems provides a “much, much better compromise” compared to 1-way systems, particularly when dealing with varied road surfaces and imperfections.

Additionally, 3-way coilovers offer an advantage as they age: when the suspension dampers begin to wear out, the available adjustment range provides “headroom” to increase settings, allowing you to “get back to where your sweet spot was”.

YellowSpeed’s Engineering for Performance

Manufacturers like YellowSpeed incorporate advanced engineering into their 3-way adjustable coilovers to ensure durability and consistent performance:

- Monotube Internal Design: Features a high-rigidity 52mm shock body, which increases oil capacity for more stable damping, contributing to agile steering and vehicle stability.

- High-Quality Materials: Piston rods are made from S45C steel, undergoing heat treatment for rigidity and durability. Springs are produced from SAE9254 high-strength steel for optimal durability and resistance to long-term wear.

- External Canisters: A key feature in their 2-way and 3-way Club Performance and Pro Plus Racing models, these external reservoirs provide increased oil volume for superior heat dissipation, ensuring stable damping rates even during prolonged, aggressive use.

Conclusion

Mastering the setup of your 3-way adjustable coilovers is an iterative process, requiring patience and meticulous observation. By understanding the distinct roles of high-speed compression, low-speed compression, and rebound, and applying a systematic adjustment methodology, drivers can unlock the full potential of their vehicle’s handling characteristics. The advanced design and material quality found in these systems provide the necessary precision and durability for demanding applications.

For those looking to explore high-performance 3-way adjustable coilovers, considering options from manufacturers like YellowSpeed, who offer various adjustable coilover solutions including their Club Performance and Pro Plus Racing 3-way systems, could be a next step. Their products feature comprehensive adjustability and robust construction designed for demanding conditions.