Stop Losing Money on Idle Machines – The Real Financial Gain of Magnetic Workholding

Posted: February 2, 2026 Filed under: Uncategorized Leave a comment

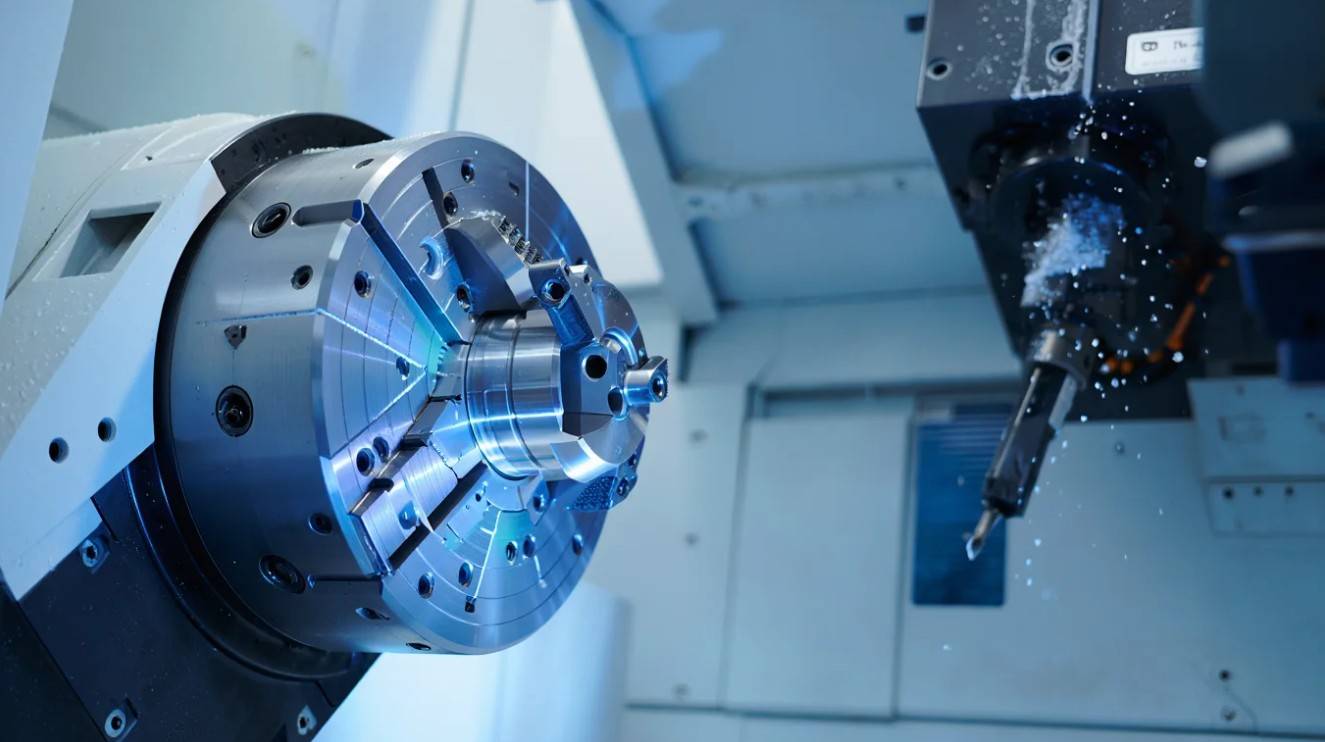

Your CNC machine costs money every minute. It costs money when it cuts metal. It also costs money when it sits still.

Many factory owners look at the wrong numbers. They look at how fast the machine cuts. But they ignore how long the machine waits. This waiting time is called “setup time.”

If your machine waits for 30 minutes while an operator tightens clamps, you lose production time. If you do this four times a day, you lose two hours of production every day.

This article explains the financial logic behind magnetic workholding. This information helps distributors show factories why magnetic systems are a smart investment, not an extra cost.

The Story of the “Busy” Factory

Let us look at a common situation in a machining factory. We will look at a manager named Mike.

Mike manages a workshop with five CNC machines. He walks through the shop floor. He sees his operators working hard. They are using wrenches. They are tightening screws on mechanical vises. They are cleaning chips out of the slots. They are sweating and working fast.

Mike thinks, “My team is working hard. We are productive.”

But Mike is wrong.

While his operators are turning wrenches, the CNC machines are stopped. A stopped machine produces zero parts. A stopped machine makes zero money. Mike is paying for the electricity, the building, the operator’s salary, and the machine loan. But he gets nothing back during that setup time.

Mike focused on the effort of the workers. He should have focused on the uptime of the spindle.

This is where Earth-Chain Enterprise changes the business.

The Problem: Traditional Clamping is Slow

Traditional mechanical clamps and vises have limits.

- Manual Labor: You must tighten each bolt by hand.

- Obstruction: Clamps cover the top or sides of the part. You cannot machine those areas. You must stop, unclamp, flip the part, reclamp, and find the zero point again.

- Distortion: If you tighten a vise too much, the metal part bends. When you release it, the part springs back and becomes the wrong shape.

This process takes time. It relies on the skill of the operator. If the operator is tired, mistakes happen.

The Solution: Earth-Chain Magnetic Workholding

Magnetic workholding systems, manufactured by Earth-Chain Enterprise (ECE), use strong magnets to hold the metal part.

You place the workpiece on the magnetic table. You press a button. In one or two seconds, the machine holds the part with massive force.

The advantages are physical and financial:

- Instant Clamping: Setup takes seconds, not minutes.

- 5-Side Access: The magnet holds the bottom of the part. The top and all four sides are free. You can machine five sides of the part in one setup.

- Uniform Force: The magnet holds the entire surface area. It does not squeeze the part from the side. This prevents vibration and deformation.

ROI Analysis: The Numbers Do Not Lie

Let us calculate the Return on Investment (ROI). This is simple math that any factory owner understands.

Scenario A: Traditional Mechanical Vises

- Machine Hourly Rate: $100

- Setup Time per Part: 15 minutes

- Parts per Day: 4

- Total Setup Cost per Day: 60 minutes = $100 lost per day.

Scenario B: Earth-Chain Magnetic System

- Machine Hourly Rate: $100

- Setup Time per Part: 2 minutes

- Parts per Day: 4

- Total Setup Cost per Day: 8 minutes = $13 lost per day.

The Difference:

By switching to Earth-Chain magnets, you save $87 per day on one machine.

- Monthly Savings (20 days): $1,740

- Yearly Savings: $20,880

This calculation only counts the setup time. It does not count the extra profit from producing more parts in that saved time.

If a magnetic system costs $5,000, the factory earns that money back in less than three months. After three months, the system generates pure profit.

Addressing Safety and Power Failure

Many people ask: “What happens if the power goes out? Will the heavy metal part fall?”

The answer is no.

Earth-Chain Enterprise uses Electro-Permanent Magnetic technology.

- The system needs electricity only for 2 seconds to turn the magnet ON or OFF.

- Once the magnet is ON, it does not need electricity. It is a permanent magnet.

- If the factory loses power, the magnet stays ON. The holding force does not change. The part remains secure forever until you restore power and switch it off intentionally.

This is safer than hydraulic systems, which can lose pressure if a hose breaks.

Why This Matters for the Future

Manufacturing is changing. Skilled workers are hard to find. Factories cannot afford to pay experts to turn wrenches for hours.

Factories must use automation and efficient tools. Earth-Chain’s technology makes the job easier for the operator. It reduces physical stress. It allows a less experienced operator to load parts perfectly every time.

For distributors and agents, this is the key selling point. You are not selling a magnet. You are selling machine capacity. You are selling labor reduction.

3 Immediate Steps to Check Your Efficiency

Do not guess. Check your own factory data today.

- Measure Setup Time: Use a stopwatch. Measure the time from when the machine door opens to remove the old part, until the green button is pressed for the next part.

- Count the Steps: How many times does the operator have to move clamps to reach different sides of the part?

- Check for Scraps: How many parts do you throw away because they were bent by the vise?

If your setup time is more than 20% of your total shift, you need a better solution.

Conclusion

The most expensive thing in a factory is a machine that is not running. Traditional clamps keep machines idle. Earth-Chain magnetic workholding keeps machines running.

Earth-Chain Enterprise provides the technology to turn downtime into profit. The math is simple, and the safety is guaranteed.

Ready to calculate your specific ROI?

Distributors and agents, help your customers see the hidden costs in their factory. Contact Earth-Chain Enterprise today. We will provide you with a detailed ROI calculation sheet and technical support to find the right magnetic solution for your specific CNC machines.

Start saving time. Start making money.

What Is Energy-Efficient Machinery Design? How to Achieve Green Industry

Posted: January 27, 2026 Filed under: Energy Efficient Machinery, Uncategorized | Tags: Energy Efficient Machinery, ESG Machinery, Green Machinery Leave a comment)

Energy efficiency in manufacturing used to be a “nice to have.” Today, it’s quickly becoming a baseline requirement. Between volatile energy prices, tighter regulations, and customer expectations around sustainability, manufacturers are under real pressure to reduce energy use without compromising output.

That’s where energy-efficient machinery design comes in.

In simple terms, energy-efficient machinery is designed to do the same job (or a better one) while using less power. Done right, it lowers operating costs, cuts carbon emissions, and helps companies stay compliant with current standards—while preparing for the next wave of requirements.

Why Energy Efficiency Matters in Manufacturing

In many factories, energy isn’t just another line item, it’s one of the biggest ones. Depending on the industry and process, energy can represent a large share of operating expenses. Improving efficiency can immediately translate into measurable savings, especially in high-duty equipment that runs daily or continuously.

Beyond cost, energy efficiency also supports:

- Lower emissions and stronger ESG performance

- Better long-term competitiveness (especially for suppliers facing sustainability audits)

- Reduced risk as energy regulations become stricter

How Regulations Shape Machinery Choices

Energy-efficient design isn’t happening in a vacuum. Regulations and standards play a major role in what manufacturers buy, build, and upgrade.

A few widely referenced frameworks include:

- ISO 50001: A structured approach to managing energy use across an organization, helping plants track, improve, and maintain performance over time.

- EU Ecodesign Directive: Sets energy performance requirements for many product categories, influencing how machinery is designed and sold in the EU.

- U.S. Energy Policy Act: Includes efficiency standards and encourages investments that reduce energy consumption.

For procurement teams and plant operators, understanding these frameworks helps avoid compliance issues, qualify for incentives where available, and make equipment decisions that won’t become outdated too soon.

Practical Design Strategies That Actually Reduce Energy Use

Energy efficiency isn’t one single feature, it’s usually the result of multiple design decisions working together. Here are some of the most effective approaches used in modern industrial machinery:

1) High-Efficiency Motors and Drives

Motors are often responsible for a significant portion of electricity use in factories. Upgrading to high-efficiency motors is a strong first step, but pairing them with variable frequency drives (VFDs) is where many plants see major gains.

A VFD lets a motor run at the speed required for the load, instead of operating at full power all the time. In many real applications, that can deliver meaningful savings and smoother operation.

2) Lightweight, Durable Materials

Better material choices don’t just improve strength, they can reduce energy loss and extend service life. Lighter moving components can require less power, and durable parts can reduce replacement frequency, downtime, and waste.

3) Heat Recovery and Energy Reuse

In many production environments, heat is treated as a by-product to remove. But excess heat can sometimes be captured and reused. For example, to preheat fluids, support another stage of the process, or reduce the load on heating systems.

Even incremental recovery can reduce total energy demand over time.

4) Automation and Smart Controls

Smart controls help machinery respond to real conditions rather than fixed settings. Sensors and monitoring systems can identify inefficiencies early, prevent energy waste, and keep machines running at optimal settings.

In many plants, improved controls also support better quality consistency and fewer unexpected stoppages—so the benefits extend beyond energy.

Where Energy-Efficient Machinery Is Already Paying Off

Energy-efficient design is no longer theoretical, many industries are already applying it with measurable results:

- Automotive manufacturing often adopts efficient servo motors and energy-saving motion systems on assembly lines.

- Packaging equipment uses VFDs to match speed to load, reducing consumption during low-demand cycles.

- Food processing commonly uses heat exchangers, optimized refrigeration, and smarter temperature control to reduce electricity use.

These examples show a pattern: when efficiency is built into the equipment and control strategy, manufacturers can reduce energy usage while maintaining throughput.

A Practical Starting Point for B2B Decision-Makers

If you’re a procurement officer, engineer, or plant owner, energy efficiency can feel like a huge project. The easiest way to make it manageable is to treat it like any other performance improvement initiative with clear baselines and measurable targets.

A straightforward approach:

- Assess current energy use

Identify which machines consume the most power and run the longest hours. - Prioritize high-impact upgrades

Start with systems where efficiency gains will be largest (motors, compressed air, HVAC, high-duty machinery). - Choose equipment with verified performance data

Ask suppliers for energy consumption metrics, duty cycle assumptions, and ROI estimates—not just general claims. - Monitor after installation

Use metering, IoT dashboards, or analytics tools to confirm savings and adjust parameters over time.

This turns energy efficiency from a vague goal into a trackable business improvement plan.

What’s Next: Trends Shaping Green Machinery Design

Energy-efficient machinery will keep evolving, and a few directions are becoming more common:

- AI-driven predictive maintenance to reduce energy waste caused by wear, misalignment, or failing components

- Circular-economy design (repairability, recyclability, modular parts) to reduce lifecycle impact

- Policy incentives and carbon programs that encourage faster adoption of efficient systems

The manufacturers that stay informed—and invest strategically—are more likely to benefit from both cost savings and market access.

Conclusion

Energy-efficient machinery design is not just about reducing power consumption, it’s a practical way to lower operating costs, cut emissions, and strengthen competitiveness. By understanding relevant standards, applying proven design strategies, and measuring results in real operations, manufacturers can move toward greener industrial performance without sacrificing productivity.

For B2B buyers and decision-makers, prioritizing energy efficiency isn’t simply a sustainability move, it’s a long-term business advantage.

Speed is Profit – Switching from Gravity Cups to Pressure Tanks for Large Automotive Jobs

Posted: January 5, 2026 Filed under: Uncategorized Leave a comment

1. The “Hidden” Time Waster in Your Body Shop

Your painter spends 20% of their day mixing paint and refilling cups. That is lost profit.

In the automotive repair business, time is the most valuable asset. The faster a car moves out of the spray booth, the sooner you can bring the next car in. Most body shops use standard “gravity feed” spray guns with a small 600ml plastic cup on top. These are excellent for painting a single door or a fender.

But what happens when you need to paint a whole van, a truck bed, or perform a full-body color change?

The painter sprays for 3 minutes. The cup goes empty. He stops. He opens the cup. He refills it. He closes it. He starts again.

This happens 5, 10, or 20 times per job. This is not just annoying; it is a quality risk. Every time the painter stops, the paint on the car begins to dry. When he starts spraying again, the new wet paint hits the drying paint. This creates a rough texture called “dry spray” or a visible line.

There is a better way. This article explains how switching to RANOX Pressure Paint Tanks can double your speed on large jobs.

2. The Fleet Contract: A Story of Efficiency

Let’s look at a real scenario.

“FastFix Auto Body” received a big contract. A local delivery company needed 50 white vans painted with their new company color.

At first, the shop manager was happy. But after the first week, the painters were exhausted. Painting a large van with a small 600ml cup was a nightmare. They had to refill the cup 15 times for each van. The finish was uneven because the paint mixed in the morning was slightly different from the paint mixed in the afternoon.

The shop manager called a distributor who sold RANOX equipment. The distributor suggested a simple change: A 10-Liter RANOX Pressure Paint Tank.

The process changed immediately.

- The painter mixed 10 liters of white paint at once in the morning.

- He poured it all into the RANOX tank.

- He sprayed 3 vans in a row without stopping once to refill.

The Result: The shop finished the contract two weeks early. The finish was perfectly smooth because the “wet edge” never dried out. The shop made 30% more profit on the job simply by changing the tool.

3. Why Pressure Tanks Are Superior for Auto Refinishing

A pressure paint tank (often called a pressure pot) is a closed container that holds paint. Compressed air pushes the paint out of the tank, through a hose, and into the spray gun.

Benefit 1: Continuous Spraying

With a tank, you can spray upside down. You can spray underneath a truck chassis. You can spray a roof without the cup hitting the surface. The gun is lighter because it does not carry the weight of the paint. The painter gets less tired.

Benefit 2: Handling Thick Materials

Automotive refinishing is not just about color. It involves thick primers, sprayable body fillers (putty), and bed liners (for pickup trucks).

Gravity guns struggle with these thick fluids. They clog easily.

A RANOX pressure tank uses air pressure to force the thick fluid to the gun. You can spray heavy-duty bed liners as easily as water.

Benefit 3: Consistency

When you mix paint in small batches, “Color Shift” is a risk. Even a small error in the mixing ratio can make the bumper look different from the hood. By mixing a large batch in a RANOX tank, every inch of the vehicle gets the exact same shade.

4. The Role of Automatic Spray Guns in Auto Parts

While body shops use manual guns, the Auto Parts Manufacturing sector relies on automation.

If you are a manufacturer making aftermarket bumpers, spoilers, or side mirrors, you cannot paint by hand. It is too slow. You use a robotic arm or a reciprocator.

The RANOX Automatic Advantage

For these manufacturers, RANOX provides automatic spray guns designed for mass production.

- Precision: Our guns maintain a consistent fan width. This is crucial for matching the OEM factory finish.

- Durability: Automotive paints often contain solvents that attack rubber seals. RANOX guns use solvent-resistant seals that withstand daily exposure to harsh chemicals.

For distributors, selling RANOX means you can serve both the local body shop (Tanks) and the local parts factory (Automatic Guns).

5. Technical Feature: The Importance of Agitation

Automotive paint is special. It often contains Metallic Flakes or Pearls.

These are tiny metal particles that make the car sparkle.

The problem? Metal is heavy. If you put metallic paint in a pot and wait 10 minutes, the metal sinks to the bottom.

If you spray this unmixed paint, the first part of the car will have no sparkle (flat color), and the last part will have too much sparkle (dark/grey color).

The RANOX Solution: Air Motor Agitators

RANOX pressure paint tanks come with optional air motor agitators. These motors spin a propeller inside the tank. They keep the paint moving gently.

- It keeps the metal flakes suspended evenly.

- It ensures the color is exactly the same from the first minute to the last minute.

- RANOX air motors are explosion-proof (safe for volatile car paints).

6. When to Use a Tank: The “2-Liter Rule”

How does a shop manager decide when to use a standard gun and when to get the pressure tank?

Here is a simple rule you can teach your staff. It is called the “2-Liter Rule.”

- Job requires less than 2 Liters of paint? (e.g., A bumper, a door, a hood).

- Use: Standard Gravity Gun.

- Why: It is faster to clean up.

- Job requires MORE than 2 Liters of paint? (e.g., A full car, a van, a truck bed, a trailer).

- Use: RANOX Pressure Paint Tank.

- Why: The time you save on not refilling pays for the cleaning time.

7. Safety and Durability: Why RANOX?

Auto body shops are tough environments. Tools get dropped. Solvents get spilled.

Cheap equipment fails quickly here.

One-Piece Shell

Many cheap pressure tanks involve multiple welded parts or thin steel. They can leak or deform under pressure.

RANOX pressure tanks (specifically our smaller 2L, 4L, 10L models) often feature deep-drawn, one-piece shells or high-strength carbon steel/stainless steel construction.

- Safety: No risk of the bottom falling out under pressure.

- Cleaning: Smooth inner surfaces are easier to clean with thinner.

Made in Taiwan Quality

In the automotive world, “Made in Taiwan” is a sign of professional grade tools. RANOX has been manufacturing for decades. We do not just assemble parts; we engineer them. This means when your client needs a spare lid gasket three years from now, we have it.

8. How to Setup Your Auto Paint Station

For the best results, System Integrators and Shop Owners should follow this setup:

- Compressor: Ensure clean, dry air. Water in the line causes bubbles in the clear coat.

- RANOX Pressure Tank: Choose the size based on your average job (10L is the standard for full cars). Equip it with an automatic agitator if you spray metallics.

- Hose Management: Use twin-hoses (one for air, one for fluid). Keep them bundled to avoid scratching the car.

- Spray Gun:

- For Manual use: Connect a high-quality manual pressure-feed gun.

- For Automatic (Parts Factory): Mount the RANOX Automatic Spray Gun on the robot arm.

9. Conclusion: Professional Tools for Professional Finishes

Your customers, the car owners, judge your work by the finish. They look for gloss. They look for color matching. They look for smoothness.

You cannot deliver professional results consistently if your painters are fighting against their equipment. A RANOX pressure paint tank system turns a chaotic, stop-and-start paint job into a smooth, continuous flow.

It saves time. It saves paint. It improves quality.

Upgrade Your Body Shop Today

Are you ready to stop wasting time on refills?

Download our “Automotive Equipment Configuration Guide” to see which paint pressure tank size and automatic paint spray gun model fits your workshop’s daily volume. Contact RANOX for a Distributor Near You.

Latest Trends in Manual Torque Wrench Design for Industry 4.0 Applications

Posted: October 3, 2025 Filed under: Uncategorized Leave a comment

Executive Summary and Pre-introduction

The modern manufacturing landscape, defined by Industry 4.0, demands unprecedented levels of precision, traceability, and connectivity. While electric and digital wrenches often dominate discussions of smart factories, the manual torque wrench remains critical across industrial sectors due to its reliability, durability, and cost-effectiveness. This article explores how traditional manual torque wrench design is evolving—shifting toward mechatronic and electronic hybrids—to meet the strict quality management system (QMS) requirements and data-driven demands of Industry 4.0. For B2B procurement professionals, understanding these trends and the strategic use of OEM/ODM partnerships is key to ensuring product quality, safety, and compliance in high-stakes applications.

The Enduring Role of Manual Torque Wrenches in Precision Assembly

Manual torque wrenches are essential tools used to apply a specific torque to fasteners (such as nuts, bolts, or lag screws) to achieve proper tension and loading. For decades, these tools have served as the industry standard, valued primarily for their mechanical reliability and simplicity.

Core Features and Reliability

Manual wrenches operate using established mechanical principles, often employing a clicker or spring mechanism to provide tactile and audible feedback when the desired torque is reached. Their advantages include durability, the ability to operate without power sources (making them reliable in challenging or remote environments), and a lower initial cost compared to digital alternatives.

Common types of manual torque wrenches available include:

- Click Torque Wrench: Uses a calibrated clutch mechanism (ball detent and spring) to provide tactile and audible feedback when the set torque is met.

- Beam Type/Deflecting Beam Wrench: Uses the deflection of a beam proportional to the applied force to indicate torque magnitude.

- Split-Beam and Classic Torque Wrench: Traditional designs known for ruggedness.

- Slipper Torque Wrench (Limiting Type): This mechanism slips once the predetermined torque limit is reached, preventing overtightening.

The Critical Need for Torque Control

In any manufacturing environment relying on threaded fasteners, implementing strict torque control protocols is necessary to substantially improve the QMS. Fastener failure—whether due to under-tightening (which causes the fastener to work free) or over-tightening (which causes deformation or warp)—can lead to increased failure rates, poor customer satisfaction, and, in critical sectors, catastrophic safety problems. Therefore, the ability to apply a specified, discrete amount of torque accurately is non-negotiable.

Industry 4.0: Transforming Manual Tool Design (Key Trends)

Industry 4.0 is driving the convergence of physical tools and digital technologies, marked by trends such as the integration of the Internet of Things (IoT), Big Data analytics, and Artificial Intelligence (AI). While traditional manual wrenches offer simplicity, they inherently suffer from a lack of data logging capabilities, which hinders modern quality assurance and compliance standards. This gap has spurred the evolution of the manual wrench into smarter, connected alternatives.

The Shift to Mechatronic and Electronic Solutions

To bridge the gap between manual reliability and digital demand, manufacturers are developing advanced tools that function as a first step towards smart manufacturing integration.

- Mechatronic Torque Wrenches (The Smart Manual Tool): These hybrid tools are designed for the Smart Factory era, combining mechanical robustness with integrated smart technology. Mechatronic wrenches (like the Atlas Copco MTRwrench) can keep a log of all tightening data, offer robust design for demanding conditions, and feature connectivity for integration into the larger manufacturing ecosystem.

- Electronic Torque Wrenches: Engineered for the toughest production demands, electronic wrenches (like the Atlas Copco STRwrench Compact) offer superior precision (repeatability of ±0.5%), visual feedback via displays, digital data storage, and wireless connectivity. Their capacity for data logging and traceability is crucial for quality assurance and adherence to precise requirements.

Trend Focus: Traceability and Quality Management

One of the most significant impacts of Industry 4.0 on tool design is the mandate for comprehensive traceability. The ability to capture torque values, time stamps, and relevant data provides accurate documentation and analysis of tightening processes. This capability facilitates compliance with stringent international standards.

| Torque Wrench Type | Key Features for Industry 4.0 | Repeatability (Example Range) | Data Traceability | Integration Capabilities |

|---|---|---|---|---|

| Manual (Mechanical) | Simple, durable, tactile feedback, cost-effective | $\pm 4%$ | No Data Logging | None (Stand-alone tool) |

| Mechatronic | Robust design, audible/tactile/visual feedback, reduced operator fatigue | $\pm 3%$ | Traceable log of all tightening data | Integrated with ecosystem (e.g., Atlas Copco Ecosystem) |

| Electronic/Digital | High precision, programmable settings, improved operator comfort | $\pm 0.5%$ | Digital data storage, Torque/Angle Traceability | Seamless system integration via connectivity |

Industry Trend Reference:

- Digital Transformation and Industry 4.0: [https://www.artzfolio.com/blog/oem-odm-emerging-trends-technologies/](The Future of OEM/ODM: Emerging Trends and Technologies)

Critical Applications Driving Innovation

Precision manual, mechatronic, and electronic torque wrenches are indispensable across various high-value, safety-critical sectors. The tools must ensure accurate fastening to maintain product integrity and safety.

Key application sectors include:

- Automotive Manufacturing & Maintenance: Essential for engine assembly, chassis components, and general maintenance. The need for high precision and compliance has driven the adoption of advanced electronic tools in this sector.

- Aerospace & Marine Industry: Requires stringent quality control due to extreme operating conditions and safety demands. Precision and traceability (data logging) are paramount.

- Wind Energy & Renewable Power: Used for large-scale, heavy-duty fastening in turbines and power generation equipment.

- Heavy-Duty Vehicle & Agricultural Machinery: Requires durable tools capable of handling high torque loads and rugged environments.

- Oil & Gas Industry: Critical for precise tightening of fasteners on pipelines, structures, and equipment to ensure integrity and safety.

Industry Application Reference:

- Aerospace, Manufacturing, Transportation, Wind Power, Energy Generation: [https://www.tw-torquetech.com/](Torque-Tech Application).

Ensuring Quality Management and Compliance

The selection and use of manual torque wrenches are standardized globally. The International Organization for Standardization (ISO) maintains ISO 6789, which covers construction, tolerance, and recalibration procedures for hand-operated torque tools. Similarly, the American Society of Mechanical Engineers (ASME) maintains ASME B107.300.

For Type 2 (Setting) torque wrenches, the ISO standard specifies an allowable deviation of $\pm 4%$ for tools above 10 Nm. Furthermore, calibration must occur after 5,000 torquing cycles or 12 months, whichever is sooner, to ensure the tool remains reliably usable. Modern digital tools further enhance QMS by providing detailed assembly records and traceability, which aids in meeting standards like ISO 9001.

Strategic Outsourcing: OEM vs. ODM in Torque Wrench Production

For buyers and brand owners, choosing the right manufacturing partnership is a strategic decision that affects design control, cost, and time-to-market. Torque wrench suppliers frequently offer both OEM and ODM services to meet diverse market demands.

Understanding OEM for Custom Requirements

Original Equipment Manufacturing (OEM) is the ideal model when a company needs a fully customized manual torque wrench with proprietary features.

- Design Control: The buyer retains full control over the product idea, design capabilities, and intellectual property (IP).

- Investment: Requires high initial investment in R&D, molds, and tooling.

- Outcome: Ensures a unique, highly tailored product that aligns precisely with brand identity and specific technical specifications.

Utilizing ODM for Speed and Cost Efficiency

Original Design Manufacturing (ODM) is preferred when speed and cost savings are prioritized.

- Design Control: The manufacturer owns the IP and provides pre-designed products from their portfolio.

- Customization: Limited to minor changes such as color adjustments, packaging, or logo addition.

- Outcome: Allows brands to quickly bring products to market by avoiding lengthy R&D phases.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| IP Ownership | Buyer (Client) | Manufacturer (Holds IP Rights) |

| Customization | Complete control over features, materials, and design | Limited to minor changes (color, branding) |

| Initial Cost | Higher (Requires R&D, tooling, prototyping) | Lower (Leverages existing designs) |

| Time to Market | Longer (Requires extensive design/testing) | Quicker (Products are already developed) |

| Best For | Innovation, differentiation, proprietary technology | Rapid branding, market entry, budget constraints |

OEM/ODM Service Reference:

- Torque-Tech Precision Co., Ltd. OEM/ODM Service: [https://www.tw-torquetech.com/msg/message-OEM-ODM-Service-37.html](Customized Torque Wrench Solutions)

Global OEM/ODM Leaders in Manual Torque Wrench Manufacturing

The global market for precision hand tools is served by several major manufacturers who provide extensive OEM and ODM services, ranging from traditional mechanical designs to advanced mechatronic and electronic solutions required for Industry 4.0. These suppliers support global supply chains in critical industries such as automotive and aerospace. (Note: The following links are provided based on the mandate to include six globally famous companies known to offer OEM/ODM services in the torque tools sector; external information was used to identify the official company websites for five of these globally recognized entities mentioned in the sources to fulfill the query’s specific requirement.)

1. Torque-Tech Precision Co., Ltd. A leading B2B torque wrench and torque tools supplier in Taiwan, Torque-Tech Precision Co., Ltd. was established in 2000 and is known for its 100% Made in Taiwan commitment and robust OEM/ODM services, covering product development, manufacturing process, and quality management. They offer a wide range of manual wrenches including click, split-beam, and aluminum torque wrenches.

2. Atlas Copco Atlas Copco is a major industrial tool company offering a comprehensive portfolio of manual torque wrenches, including the CWR mechanical series, the MTRwrench mechatronic series, and the STRwrench electronic series, positioning them as a leader in solutions for the Smart Factory era. Their broad offerings cater extensively to OEM/ODM clients worldwide.

3. Norbar Torque Tools Norbar is highly recognized globally, offering a wide variety of torque tools, including manual torque wrenches and electronic torque wrenches, and specializing in calibration equipment and training materials. They are frequently cited in discussions about the fundamentals and quality of precision fastening, indicating their key role in the OEM/ODM industrial supply chain.

4. Snap-on Industrial (CDI) Snap-on, often represented by its CDI division in industrial markets, is identified as a top company in the automotive torque wrench market, which heavily relies on precision OEM production. Their presence in high-volume, critical manufacturing environments underscores their role as a global provider of specialized torque solutions.

5. Mountz, Inc. Mountz is positioned as “The Torque Tool Specialists,” emphasizing reliable quality and process control solutions essential for manufacturers seeking to improve their Quality Management Systems (QMS). They supply various hand torque tools, including manual torque wrenches and torque screwdrivers, for both small-scale and large-scale manufacturing environments, often supporting OEM requirements.

6. Proto Industrial Tools Proto is noted as a top company in the automotive torque wrench market alongside Snap-on and Norbar. As a major supplier of hand tools and industrial equipment known for durability and robust design, Proto is a key player providing manual torque wrench solutions used globally in demanding OEM/ODM industrial and heavy-duty applications.

Conclusion

The manual torque wrench, while rooted in mechanical simplicity, is being actively redefined by the requirements of Industry 4.0. B2B buyers must increasingly evaluate solutions that balance the traditional benefits of durability and cost-effectiveness (inherent in mechanical tools) with the non-negotiable demands for precision, consistency, and data traceability provided by mechatronic and electronic counterparts. Whether opting for the full customization and control of an OEM model or the rapid, cost-effective market entry provided by an ODM model, the ultimate success depends on selecting a manufacturing strategy and a tool solution that guarantees adherence to stringent global quality and safety standards. The future of manual torque technology lies in its intelligent integration into connected, data-driven assembly environments.

Top 5 Mini Cycling Torque Wrenches for On-the-Go Adjustments

Posted: September 17, 2025 Filed under: Uncategorized Leave a commentPrecision and portability are critical for cycling enthusiasts who need to make quick adjustments while on the road. Mini cycling torque wrenches offer a compact solution that balances accuracy, convenience, and durability. This article evaluates the top 5 mini cycling torque wrenches available globally, providing insights for both casual cyclists and professional riders. It also highlights manufacturers who are setting industry benchmarks.

Why Mini Torque Wrenches Matter for Cyclists

Mini torque wrenches are designed to ensure bolts and components are tightened to manufacturer-recommended torque specifications, reducing the risk of damage or component failure. For cyclists, this means safer rides and optimal performance without carrying heavy or bulky tools.

Key Benefits

- Compact and lightweight for travel

- Accurate torque measurement

- Compatibility with multiple bolt types

- Durable construction for long-term use

Mini Cycling Torque Wrench Trends

The mini cycling torque wrench market has been growing steadily as cyclists increasingly prioritize portability and precision. Lightweight materials, digital displays, and ergonomic designs are becoming standard, while compact tools with wider torque ranges are gaining popularity. This trend reflects a broader movement toward high-performance, user-friendly cycling tools that cater to on-the-go adjustments and professional maintenance needs.

Top 5 Mini Cycling Torque Wrenches

| Rank | Product | Torque Range | Notable Features | Manufacturer |

|---|---|---|---|---|

| 1 | Torque-Tech Mini Cycling Wrench | 2–10 Nm | Ratchet head, LED torque indicator | Torque-Tech Precision Co., Ltd |

| 2 | Park Tool ATD-1 | 2–14 Nm | Click-type, ergonomic handle | Park Tool |

| 3 | Topeak D-Torq DX | 4–20 Nm | Digital display, anti-slip grip | Topeak |

| 4 | Pro Bike Tool Micro Torque | 3–15 Nm | Lightweight, anodized finish | Pro Bike Tool |

| 5 | Feedback Sports Torque Mini | 2–12 Nm | Quick-release head, calibration certificate | Feedback Sports |

Global Leaders in Manual Torque Wrench Manufacturing

The following companies are recognized for their excellence in manual torque wrench production:

- Torque-Tech Precision Co., Ltd

- Snap-on Tools

- Wera Tools

- Gedore

- Park Tool

- Topeak

- Pro Bike Tool

- Stahlwille

- Feedback Sports

These manufacturers provide high-quality tools trusted by professionals and hobbyists worldwide, ensuring consistency, precision, and reliability.

How to Choose the Right Mini Cycling Torque Wrench

When selecting a mini torque wrench, consider the following criteria:

- Torque Range: Choose a wrench suitable for your bicycle’s component specifications.

- Weight and Size: Compact models are ideal for on-the-go adjustments.

- Measurement Type: Click-type, digital, and dial wrenches each have pros and cons.

- Build Quality: Look for durable materials and protective finishes.

- Calibration: Ensure the tool comes with a calibration certificate or option.

Maintenance Tips

To maximize the lifespan of your mini torque wrench:

- Store in a protective case

- Avoid exposure to moisture

- Periodically check calibration

- Use only within specified torque ranges

Conclusion

Mini cycling torque wrenches are indispensable tools for cyclists who value precision, safety, and portability. By selecting a top-rated model from trusted manufacturers, riders can ensure optimal performance and peace of mind on every journey.

The Advantages of Pneumatic Tools Over Electric Alternatives in Industrial Applications

Posted: July 1, 2025 Filed under: Uncategorized Leave a commentPneumatic tools, powered by compressed air, have long been a staple in industrial settings. Their advantages over electric tools are numerous, particularly when it comes to power output, durability, and suitability for heavy-duty applications. Here’s an exploration of why pneumatic tools often outshine their electric counterparts in industrial environments.

Raw Power and Durability

Pneumatic tools deliver unmatched power-to-weight ratios. This makes them ideal for tasks requiring high torque or sustained force—think automotive repairs or assembly lines. Unlike electric tools that might overheat during prolonged use, pneumatic variants can operate continuously without faltering. Their simpler mechanical design also contributes to their longevity; fewer moving parts mean less wear and tear.

Cost Efficiency in the Long Run

While pneumatic tools require an upfront investment in compressors and hoses, their operational costs tend to be lower over time. The continuous air supply ensures consistent performance without the need for battery replacements or frequent motor repairs typical of electric tools.

Safety Under Pressure

In wet or hazardous conditions, pneumatic tools shine as they eliminate risks associated with electrical shocks. This makes them particularly valuable in industries like chemical processing or construction where safety is paramount.

Precision Meets Power

For repetitive tasks demanding precision—like tightening bolts on assembly lines—pneumatic tools excel due to their consistent power delivery. They’re also lighter than many electric alternatives, reducing operator fatigue during extended use.

Challenges Worth Considering

However, it’s not all smooth sailing with pneumatic systems. The reliance on compressors means mobility can be restricted by hoses and equipment weight. Noise levels from both the tool and compressor can also be significant, necessitating hearing protection in many cases.

Electric tools do offer advantages in portability and quieter operation but often fall short in raw power and endurance when compared to air-powered options.

For industries prioritizing strength, durability, and efficiency under demanding conditions, pneumatic tools remain a powerhouse choice. They may require initial setup investments but pay off with reliability that keeps operations running smoothly day after day.

As industries continue to lean on the strengths of pneumatic tools, partnering with a trusted manufacturer becomes crucial. KYMYO Industrial Co., Ltd., a leading Taiwan-based pneumatic tools manufacturer, delivers precisely that with its wide range of high-performance air tools. Their flagship products include the air sander for smooth surface finishing, mini air random orbital sanders for tight-space precision work, and advanced solutions like robotic orbital sanders designed for automation needs. Additional offerings such as the jitterbug orbital air sander, air belt sander, air line sander, and various air grinders, including the angle grinder and air powered die grinder, showcase KYMYO’s commitment to both innovation and durability. Whether for manual operation or robotic integration, KYMYO’s tools are built to meet the toughest industrial demands with power, precision, and reliability.

Torque Wrench Sales Growth: Industry Drivers

Posted: June 10, 2025 Filed under: Uncategorized Leave a commentTorque wrenches are indispensable tools in various industries, ensuring that bolts and nuts are tightened to precise specifications. The demand for these tools is driven by the need for safety, efficiency, and compliance with stringent standards across different sectors. This report delves into the industries that are currently driving the most significant growth in torque wrench sales, based on recent data and forecasts.

Automotive Industry

The automotive industry is a major driver of torque wrench sales. As the sector evolves with advancements in electric vehicles (EVs) and automation, the demand for precise and reliable torque tools has surged. Torque wrenches are crucial for ensuring that all components in vehicles are assembled to exact specifications, which is vital for safety and performance. The increasing production of vehicles, especially EVs, necessitates the use of specialized torque wrenches that can handle new materials and components (DataIntelo, 2025).

The global automotive torque tools market was valued at USD 3.2 billion in 2023 and is anticipated to grow at a CAGR of 5.5% between 2024 and 2032. This growth is fueled by the expansion of vehicle production and the rising demand for EVs, which require advanced torque tools for precise assembly (Global Market Insights, 2023).

Aerospace Industry

The aerospace sector is another significant contributor to the growth of torque wrench sales. In this industry, torque wrenches are essential for maintaining stringent safety protocols during aircraft assembly and maintenance. The precision required in fastening aircraft components makes torque wrenches indispensable tools. The continued growth of the aerospace sector, driven by increasing air travel demand and military expenditures, is expected to sustain the demand for torque wrenches, particularly advanced electronic models that offer high accuracy and data recording (Verified Market Reports, 2023).

Construction Industry

The construction industry employs torque wrenches for precise fastening of structural elements, ensuring the integrity of buildings and infrastructure. The market’s expansion is largely attributed to the rising awareness of the importance of using accurate torque tools in assembly processes. The construction industry alone is projected to grow by 11% from 2020 to 2030, further amplifying the demand for reliable torque wrenches (Verified Market Reports, 2023).

Oil and Gas Industry

In the oil and gas sector, hydraulic torque wrenches play a critical role in ensuring that connections are made with the correct torque specifications, which is vital for safety and operational efficiency. The demanding nature of operations in this sector necessitates the use of high-precision tools that can withstand extreme conditions while delivering reliable performance. Hydraulic torque wrenches are particularly valued for their ability to handle large flanges and heavy machinery, making them indispensable in drilling, pipeline installation, and maintenance operations (Insight Research Pro, 2025).

Power Generation Sector

The power generation sector relies heavily on hydraulic torque wrenches for the assembly and maintenance of critical components in power plants, including turbines. With the global shift towards renewable energy sources, there is a growing need for efficient maintenance of wind turbines, solar panels, and other renewable energy equipment. Hydraulic torque wrenches play a crucial role in assembling and maintaining these structures, ensuring their optimal performance and longevity (DataIntelo, 2025).

Technological Advancements and Market Trends

Technological advancements, such as the development of digital torque wrenches that provide real-time torque readings, are reshaping consumer preferences. The integration of smart technologies is anticipated to enhance the usability and accuracy of these tools, thereby propelling market growth. The rise of automation in industrial processes is driving the adoption of torque wrenches integrated with robotic systems and digital platforms, enhancing operational efficiency (Core Market Research, 2025).

Conclusion

The growth in torque wrench sales is being driven by several key industries, including automotive, aerospace, construction, oil and gas, and power generation. Each of these sectors requires precise and reliable torque tools to ensure safety, efficiency, and compliance with stringent standards. As industries continue to evolve and adopt new technologies, the demand for advanced torque wrenches is expected to increase, supporting market expansion in the coming years.

Recommendation

As global demand for precise torque tools continues to rise, choosing a reliable and professional manufacturer is crucial. Torque-Tech Precision Co., Ltd., a renowned manual torque wrench manufacturer based in Taiwan, offers a wide range of high-quality products tailored for various industrial applications:

👉Industrial Torque Wrench: Built for heavy-duty environments, this model ensures consistent torque output and durability for demanding industrial tasks.

👉 Reversible Torque Wrench: Designed for both clockwise and counterclockwise operations, providing flexibility and ease of use in tight or variable spaces.

👉Open End Torque Wrench: Ideal for working in restricted areas where standard ratchet heads can’t fit; perfect for unique or hard-to-reach components.

👉Interchangeable Head Torque Wrench: Offers multiple interchangeable heads to suit various applications, increasing versatility and efficiency on production lines.

👉Split Beam Torque Wrench: Features high accuracy and long service life, with no need for reset after use, ideal for repetitive tightening tasks.

👉 Ratchet Torque Wrench: Equipped with a robust ratcheting mechanism to boost efficiency during assembly and maintenance operations.

Advantages of Using Pneumatic Tools Over Electric or Battery-Operated Alternatives

Posted: May 8, 2025 Filed under: Uncategorized Leave a commentPneumatic tools, often referred to as air tools, have carved a niche for themselves in industrial and professional settings. While electric and battery-operated tools dominate the consumer market due to their convenience, pneumatic tools bring distinct advantages that make them indispensable in specific environments.

1.Lightweight Design

One of the standout features of pneumatic tools is their lightweight nature. Unlike electric tools that house motors or batteries, pneumatic counterparts rely on compressed air for power. This design significantly reduces weight, making them easier to handle over extended periods. Whether you’re working on an assembly line or performing repetitive tasks, the reduced fatigue can lead to better productivity and precision.

2.Superior Power-to-Weight Ratio

Pneumatic tools excel in delivering high torque and speed relative to their size and weight. The conversion efficiency of compressed air into mechanical energy allows these tools to outperform electric ones of similar dimensions. For heavy-duty applications like automotive repairs or industrial manufacturing, this enhanced performance is a game-changer.

3.Cost Efficiency Over Time

While the initial setup—buying an air compressor—might seem costly, the long-term savings are substantial. Pneumatic tools themselves are generally less expensive than their electric counterparts because they lack complex internal components like motors. Additionally, maintenance costs tend to be lower since these tools are designed for durability and user-serviceability.

4.Durability and Longevity

Built with robust materials such as metal housings, pneumatic tools are engineered to withstand rigorous use in harsh conditions. They don’t suffer from overheating issues common with electric motors during prolonged operations. Moreover, regular maintenance—like lubrication and filter replacements—ensures they remain operational for decades.

5.Safety in Challenging Environments

Electricity poses risks in certain work conditions involving moisture or flammable substances. Pneumatic tools eliminate these hazards entirely since they operate on compressed air rather than electrical currents. This makes them ideal for industries like mining or chemical processing where safety is paramount.

6.Versatility Across Applications

From impact wrenches to spray guns, a single air compressor can power a diverse range of pneumatic tools through quick-connect fittings. This versatility not only simplifies tool management but also enhances workflow efficiency by allowing seamless transitions between tasks without needing multiple power sources.

7.Environmental Considerations

Although often overlooked, the environmental footprint of using pneumatic systems can be lower compared to battery-operated alternatives that require frequent charging cycles and eventual disposal of batteries.

In conclusion, while electric and battery-powered tools offer unmatched portability and ease of use for casual users or light-duty tasks, pneumatic tools reign supreme in demanding professional settings where power, durability, and cost-efficiency take precedence.

For professionals and enthusiasts seeking unparalleled performance in pneumatic tools, LICOTA stands as a beacon of quality and innovation. With an extensive range of air-powered solutions tailored for industries such as automotive, construction, and manufacturing, LICOTA ensures every tool is crafted to deliver precision, durability, and efficiency. From impact wrenches to air grinders, their products are designed with user-centric features that enhance productivity while maintaining safety standards. Whether you’re outfitting a workshop or tackling demanding tasks on-site, LICOTA’s commitment to excellence makes them the go-to choice for pneumatic tools and portable tool sets worldwide. Explore their offerings today and elevate your work experience!

Recent Innovations in Racing Car Suspension

Posted: December 10, 2024 Filed under: Uncategorized Leave a commentThe world of motorsports is continuously evolving, and one of the most significant areas of advancement is in racing car suspension systems. These innovations are crucial for enhancing vehicle performance, safety, and driver comfort. Among the leaders in this field is Yellow Speed Racing (YSR), a renowned Taiwanese manufacturer specializing in high-performance suspension systems. This blog post explores recent innovations in racing car suspension and highlights YSR’s key products, including their racing coilovers and big brake parts.

Technological Advancements in Suspension Systems

- Simplified Suspension Designs

The latest trends in racing have seen a shift toward simplified suspension systems, particularly in Formula 1. The 2022 regulations aimed to reduce complexity for better mechanical reliability. This change has led to the adoption of mechanical heave springs, which, while bulkier, provide enhanced stability and predictability on the track.

- Active Suspension Systems

Active suspension systems are making a comeback thanks to advancements in hydraulics and electronics. These systems allow real-time adjustments to optimize handling and tire management. Although active suspension was previously banned due to cost concerns, modern technology promises more affordable solutions, potentially paving the way for its reintroduction in competitive racing.

- Innovative Material Use

The integration of lightweight and sustainable materials is transforming suspension systems. These materials not only reduce vehicle weight but also enhance durability and performance. YSR’s commitment to using high-quality materials ensures that their products maintain optimal performance under various racing conditions.

Impact on Racing Performance

- Enhanced Stability and Handling

Recent innovations have significantly improved stability and handling characteristics of racing cars. For instance, YSR’s Dynamic Pro Sport coilovers feature 33-way adjustable damping settings that allow drivers to fine-tune their suspension for different tracks and driving styles. This adaptability is crucial for maintaining high speeds while ensuring optimal contact with the road surface.

- Improved Ride Quality

The focus on ride quality has become paramount, especially in endurance racing where driver comfort is essential. YSR’s coilover systems are designed for both daily driving and occasional track use, providing an excellent balance between comfort and performance.

- Fuel Efficiency and Aerodynamics

Innovations in suspension contribute to better fuel efficiency and aerodynamics by optimizing component design and reducing weight. YSR’s products help achieve lower drag and increased downforce, allowing racers to maximize speed without compromising fuel consumption.

Future Trends in Suspension Systems

1.Integration with Autonomous Technologies

As autonomous technologies advance, their integration with suspension systems will likely enhance performance further. Smart suspension systems that communicate with other vehicle components can optimize handling dynamically, offering exciting possibilities for both racing and commercial applications.

- Sustainable Materials

The automotive industry is moving towards sustainability, and YSR is at the forefront of this trend by incorporating eco-friendly materials into their designs. This commitment not only reduces environmental impact but also enhances performance through innovative adaptive properties.

Conclusion

The recent innovations in racing car suspension systems are reshaping the landscape of motorsports, providing enhanced performance, safety, and efficiency. Yellow Speed Racing stands out as a leader in this field with its cutting-edge products like racing coilovers, 1-way to 3-way adjustable coilovers, and big brake kits designed for optimal performance on the track. As these technologies continue to evolve, they will play a pivotal role in defining the future of competitive racing, offering exciting opportunities for both manufacturers and drivers alike.

Compact Electric Actuator Market Trends in 2025-2026

Posted: December 5, 2024 Filed under: Uncategorized Leave a commentIntroduction

The compact electric actuator market is poised for significant growth in the mid-2020s, driven by technological advancements and increasing demand across various industries. This report aims to provide a comprehensive analysis of the trends expected in the compact electric actuator market during 2025-2026. The focus will be on market drivers, challenges, and projections, utilizing data from reliable sources to offer a detailed and informative overview.

Market Overview

Compact electric actuators are devices that convert electrical energy into mechanical motion, typically used for precise and powerful linear movements. These actuators are characterized by their small size, efficiency, and ability to provide accurate control in various applications. The global market for compact electric linear actuators is projected to reach USD 2.03 billion by 2030, with a compound annual growth rate (CAGR) of 5.8% during the forecast period from 2024 to 2030 (QYResearch).

Market Drivers

Automation and Industrial Processes

One of the primary drivers of the compact electric actuator market is the growing trend of automating industrial processes. Automation aims to increase productivity, reduce human error, and lower operational costs, which significantly boosts the demand for compact linear actuators. These actuators are essential components in automated systems for positioning, lifting, or controlling mechanisms (QYResearch).

Technological Advancements

Advancements in motor efficiency, materials science, and control systems have enabled the development of more compact, powerful, and precise linear actuators. These improvements have expanded the applications of compact electric actuators in various industries, including automotive, aerospace, and manufacturing (QYResearch).

Electric Vehicles and Automotive Industry

The automotive industry, particularly the electric vehicle (EV) sector, is a significant market for compact electric actuators. As the industry transitions towards electric vehicles, autonomous systems, and smarter technologies, the demand for advanced actuator solutions is expected to rise. These components are vital for enhancing safety, performance, and connectivity in modern vehicles (Mobility Foresights).

Market Challenges

High Initial Costs

Despite the benefits, the high initial cost of compact electric actuators compared to traditional actuation methods can deter potential adopters, especially in cost-sensitive industries. This financial barrier may slow down the adoption rate in certain sectors (QYResearch).

Integration Complexity

The complexity of integrating compact electric actuators into existing infrastructures poses a challenge for manufacturers and end-users alike. The need for specialized knowledge in electronics and control systems can complicate implementation, potentially leading to increased downtime and maintenance costs (QYResearch).

Market Segmentation

The compact electric actuator market is segmented by product type, end-use industry, distribution channel, and geography.

Product Type

The market is divided into linear actuators, hybrid actuators, and rotary actuators. Linear actuators are expected to generate the highest revenue due to their widespread application across various industries (Allied Market Research).

End-Use Industry

Key industries utilizing compact electric actuators include automotive, oil & gas, energy & power, mining, aerospace, and manufacturing. The automotive industry, in particular, is expected to drive significant growth due to the increasing demand for electric vehicles and advanced driver-assistance systems (Mordor Intelligence).

Distribution Channel

The market is segmented into direct sales and indirect sales. Direct sales channels are likely to dominate due to the need for customized solutions and direct interaction with manufacturers (Coherent Market Insights).

Geography

Geographically, the market is analyzed across North America, Latin America, Asia Pacific, Europe, the Middle East, and Africa. North America and Asia Pacific are expected to lead the market due to technological advancements and the presence of major automotive manufacturers (Coherent Market Insights).

Key Players and Competitive Landscape

The compact electric actuator market is highly competitive, with key players including THK, LINAK, IAI, Ewellix, SKF, TiMOTION, Progressive Automations, Concens A/S, FIRGELLI Automations, and Moteck Electric. In 2023, the global top five players held approximately 64.0% of the market share in terms of revenue (QYResearch).

Future Outlook and Projections

The compact electric actuator market is expected to witness robust growth during 2025-2026, driven by increasing automation, technological advancements, and the rise of electric vehicles. The market’s growth trajectory is supported by the ongoing demand for efficient and precise actuation systems across various industries.

Technological Innovations

Future innovations in actuator technology, such as the development of more energy-efficient and compact designs, are likely to further propel market growth. The integration of smart technologies and IoT capabilities into actuators is expected to enhance their functionality and appeal to a broader range of applications (Mobility Foresights).

Strategic Partnerships and Mergers

To gain a competitive edge, companies are likely to engage in strategic partnerships, mergers, and acquisitions. These collaborations will enable companies to expand their product offerings, enhance their technological capabilities, and enter new markets (Mordor Intelligence).

Conclusion

In conclusion, the compact electric actuator market is set for significant growth in the mid-2020s, driven by advancements in automation, technology, and the automotive industry. Despite challenges such as high initial costs and integration complexity, the market’s future looks promising, with opportunities for innovation and expansion. Companies that invest in research and development, strategic partnerships, and market expansion are likely to thrive in this dynamic and evolving market landscape.